Understand Custom Metal Fabrication

Custom metal fabrication involves designing and creating metal components or parts tailored to specific needs. This process typically uses materials such as carbon steel, stainless steel, aluminum, or copper.

Fabrication projects are designed using computer-aided design (CAD) software, allowing for almost limitless possibilities in shape and complexity. Common fabrication techniques include:

- Drilling

- Casting

- Punching

- Welding

- Milling

- Cutting

- Riveting

By combining machine and hand methods, fabricators achieve highly accurate and detailed results, ensuring that your components meet the exact specifications of your project

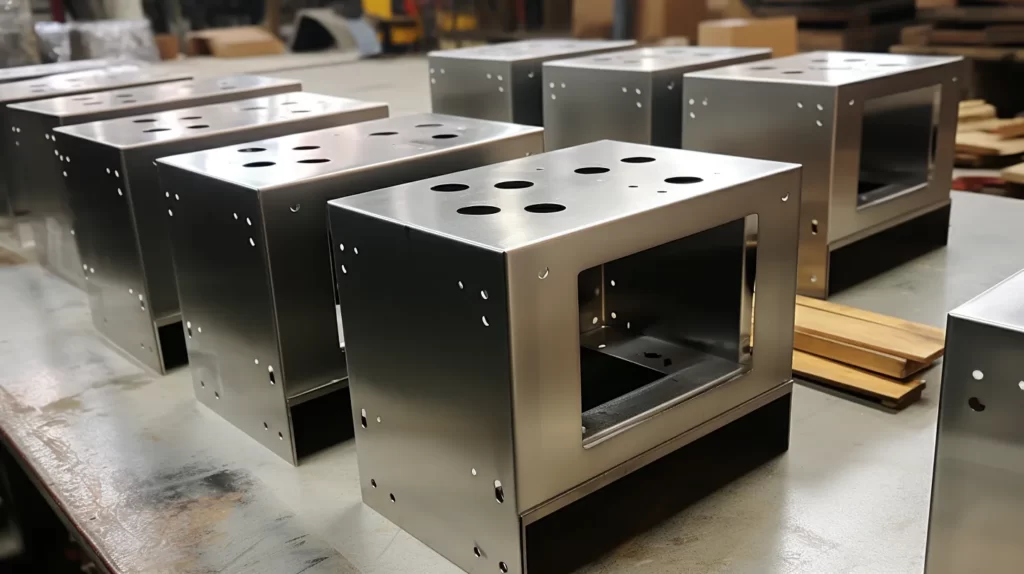

Applications of Custom Metal Fabrication

Custom fabrication allows businesses to create components entirely tailored to their unique needs. Examples of applications include:

- Heavy equipment and machinery

- Electronics enclosures

- Fencing and railing

- Office furniture

- Panels (indoor and solar)

- Automotive parts

Custom metal fabrication is highly versatile and can deliver solutions across industries such as construction, robotics, aerospace, and food service.

Benefits of Custom Metal Fabrication

Customization

Unlike mass-produced components, custom fabrication allows you to create parts specifically suited to your project. This level of flexibility is especially valuable for unique designs or applications where pre-made options don’t exist.

Cost Efficiency

Although custom solutions may seem more expensive upfront, they can save costs in the long term. Ordering directly from fabricators eliminates the middleman, reducing overhead expenses and potential supply chain delays.

Faster Turnaround Times

Working with a custom fabricator streamlines the production process. Without multiple intermediaries, you benefit from shorter lead times and quicker delivery.

Higher Quality

Custom metal components often boast higher quality than mass-produced counterparts. Fabricators focus on precision, attention to detail, and durability, ensuring that your components perform as expected.

10 Things to Know Before Investing in Metal Customization Services

1. Define Your Project Goals Clearly

Before diving into custom metal fabrication services, you need to have a clear understanding of your project goals. Are you looking for structural components, decorative elements, or functional machinery parts? Defining the purpose will guide your decisions on materials, design, and the customization process. Having precise specifications will also help the service provider deliver results that align with your expectations.

2. Choose the Right Material

Selecting the right material is one of the most critical aspects of custom metal frabrication. Factors like durability, strength, corrosion resistance, and aesthetic appeal should be considered. For instance:

- Stainless steel is excellent for corrosion resistance and a polished finish.

- Aluminum is lightweight and suitable for transportation and construction.

- Carbon steel is cost-effective and durable for heavy-duty applications.

Consult your provider to determine the material best suited to your needs.

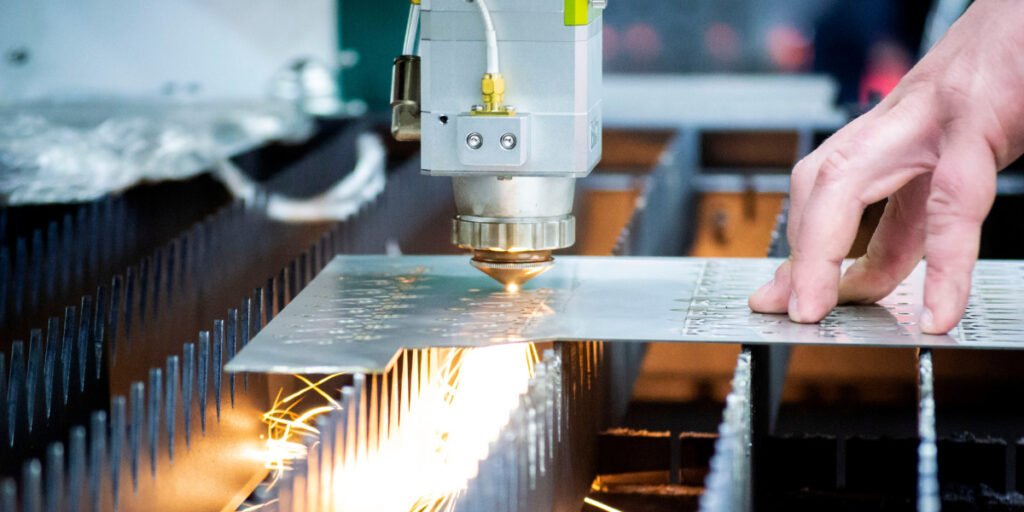

3. Understand the Customization Techniques

Different customization methods yield varying results, depending on the project’s complexity. Common techniques include:

- Laser cutting: Offers precision and clean edges for intricate designs.

- CNC machining: Provides high accuracy for complex parts.

- V-cutting and bending: Perfect for creating sharp edges and angles.

- Welding and assembly: Essential for combining multiple components.

Knowing which method suits your requirements ensures the best outcomes.

4. Assess the Service Provider’s Expertise

Choosing a reliable and experienced custom metal fabrication provider is crucial. Look for companies that:

- Have a proven track record in your industry.

- Utilize advanced machinery and technologies.

- Employ skilled engineers and technicians.

Lux Metal, for example, has a state-of-the-art facility equipped with CNC machines, laser cutting tools, and precision equipment, ensuring high-quality results for every project.

5. Verify Quality Standards

Metal customization projects require precision and adherence to quality standards. Ensure your provider complies with international standards such as ISO certifications. Ask about their quality control processes, including:

- Inspection of raw materials.

- Testing of finished products.

- Ensuring durability, accuracy, and safety.

Quality assurance guarantees your investment is worthwhile and meets your requirements.

6. Evaluate the Cost

While cost is an essential factor, it shouldn’t be the sole determinant. The cheapest option may compromise quality and durability. Instead, opt for a provider that offers a balance between cost-effectiveness and quality. Request a detailed quotation that includes:

- Material costs.

- Labor charges.

- Equipment usage fees.

A transparent pricing structure prevents unexpected expenses and ensures value for money.

7. Discuss Lead Times and Deadlines

Time is a critical factor in most projects. When choosing a customization service, ensure they can meet your timeline without compromising quality. Discuss lead times for:

- Material procurement.

- Design approvals.

- Fabrication and finishing.

Reliable providers will offer realistic timelines and update you regularly on project progress.

8. Explore Design Capabilities

Customization is all about getting a product that meets your exact specifications. Check if the service provider has an in-house design team or works closely with designers to refine your ideas. Features to look for include:

- 3D modeling and rendering capabilities.

- Flexibility to handle complex or creative designs.

- Assistance with optimizing designs for cost efficiency and functionality.

A strong design phase ensures the final product aligns perfectly with your vision.

9. Environmental Considerations

Sustainability is becoming increasingly important in manufacturing. Ask your service provider about their environmental practices, such as:

- Recycling metal scraps.

- Using energy-efficient machinery.

- Compliance with environmental regulations.

Lux Metal, for instance, is committed to eco-friendly practices, ensuring minimal environmental impact throughout the customization process.

10. Long-Term Support and Maintenance

After-sales support is a key factor in ensuring your investment pays off in the long run. Choose a provider that offers:

- Maintenance services for customized metal components.

- Technical support for installation or troubleshooting.

- Guidance on extending the lifespan of your metal products.

This level of support adds value to your investment and enhances the durability of your customized solutions.

Why Choose Lux Metal Group for Custom Metal Fabrication?

At Lux Metal Group, we specialize in creating custom metal solutions tailored to your unique requirements. With advanced machinery, skilled engineers, and a commitment to quality, we provide efficient and cost-effective results.

We offer services such as laser cutting, CNC machining, welding, and more. Whether you need heavy equipment, automotive parts, or decorative components, Lux Metal Group has the expertise to bring your vision to life.

Ready to Invest in Custom Metal Fabrication?

If you have a project in mind or need custom metal parts, Lux Metal Group is here to help. Our experienced team will work with you to design, fabricate, and deliver the perfect solution for your business.

Explore our services today at Lux Metal Group.