1. Malaysia’s Strengths in the Metal Industry

Advanced Manufacturing Capabilities

First strategy of How Malaysia Competes with Southeast Asian Countries in Metal Sheet and Precision Metal Export Businesses. Malaysia has developed a reputation for producing high-quality metal sheets and precision metal products. Its manufacturing sector integrates cutting-edge technologies, such as:

- CNC (Computer Numerical Control) Machining for precision fabrication.

- Robotics and Automation to enhance efficiency and quality.

- AI and IoT-Driven Processes to monitor production and ensure consistency.

These advanced capabilities give Malaysia an edge over competitors like Indonesia and the Philippines, which are still developing their technological base.

Reference: Automation System: The Future of Production in Malaysia

High-Quality Standards

Malaysian manufacturers adhere to strict international standards, including:

- ISO 9001: Quality management systems.

- ISO 14001: Environmental management systems.

- ISO/TS 16949: Standards for the automotive sector.

This focus on quality enables Malaysia to serve industries with stringent requirements, such as aerospace, automotive, and electronics.

Skilled Workforce

Malaysia’s commitment to education and workforce development provides a steady supply of skilled labor. Institutions like:

- Universiti Teknologi Malaysia (UTM),

- TVET (Technical and Vocational Education Training) Programs, and

- Private Industrial Training Institutes

…train workers in advanced metalworking techniques, giving Malaysia a competitive advantage in producing complex and precision-driven products.

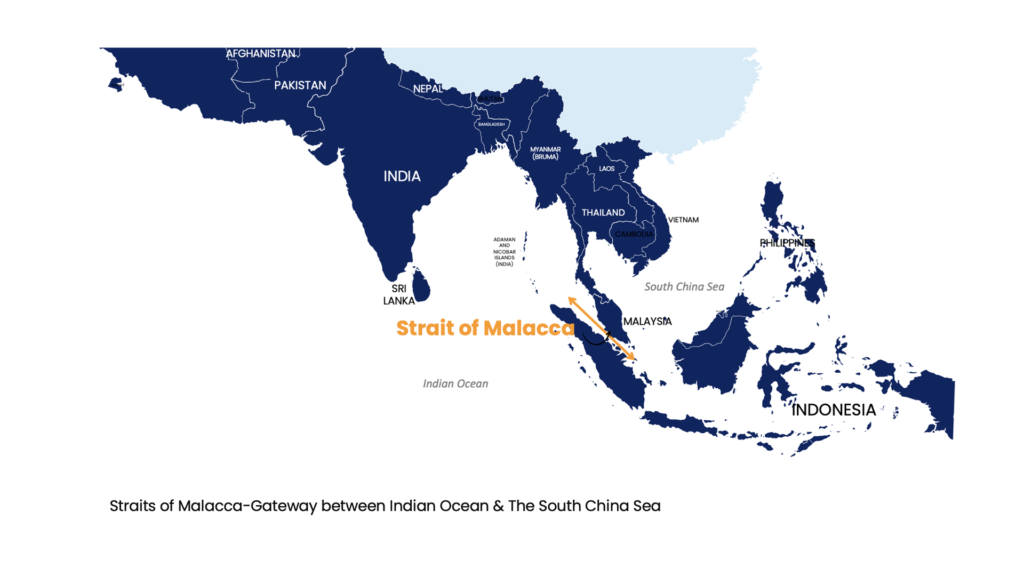

Strategic Location and Logistics

Malaysia’s strategic position in Southeast Asia, with access to global shipping lanes via Port Klang and Tanjung Pelepas Port, ensures efficient exports to major markets like the USA, Europe, and the Middle East.

Reference: The Role of Malaysia’s Strategic Location in Global Supply Chains

2. How Malaysia Competes with Vietnam

Vietnam’s Strengths

Vietnam has become a global manufacturing hub, driven by:

- Low labor costs.

- Strong foreign direct investment (FDI), particularly from companies looking to diversify supply chains away from China.

- Trade agreements like the EU-Vietnam Free Trade Agreement (EVFTA) and Comprehensive and Progressive Agreement for Trans-Pacific Partnership (CPTPP).

Malaysia’s Competitive Edge

- High-Tech Manufacturing: While Vietnam excels in high-volume, cost-effective manufacturing, Malaysia focuses on high-tech and precision-driven exports, such as aerospace components and medical devices.

- Quality Over Quantity: Malaysia’s adherence to global standards makes it a preferred supplier for industries requiring reliability and precision.

- Diversified Economy: Malaysia’s economy is less reliant on textiles or low-end manufacturing, allowing it to focus on high-value sectors, including precision metal fabrication.

3. How Malaysia Competes with Thailand

Thailand’s Strengths

Thailand is a manufacturing powerhouse in Southeast Asia, particularly in the automotive and electronics sectors. It is known for:

- A well-established industrial base.

- Strong infrastructure.

- Government initiatives to boost manufacturing through its Thailand 4.0 strategy.

Malaysia’s Competitive Edge

- Aerospace and Precision Metalwork: While Thailand leads in automotive parts, Malaysia is a dominant player in aerospace precision manufacturing, which requires higher technical expertise.

- Skilled Workforce: Malaysia’s technical education programs ensure a steady pipeline of skilled labor, often more specialized than in Thailand.

- Trade Agreements: Malaysia’s participation in agreements like RCEP and its strong ties with Western markets allow it to compete effectively in exporting high-value products.

4. How Malaysia Competes with Indonesia

Indonesia’s Strengths

Indonesia, with its vast natural resources and low production costs, has a strong position in the raw materials market. It is a major exporter of raw steel and aluminum, as well as semi-finished metal products.

Malaysia’s Competitive Edge

- Value-Added Products: Malaysia focuses on exporting value-added products, such as finished metal sheets and precision components, rather than raw materials.

- Higher Productivity: Malaysia’s factories are more technologically advanced, allowing for greater efficiency and lower defect rates than Indonesia’s labor-intensive production processes.

- Environmental Standards: Western markets increasingly demand sustainable and environmentally friendly products. Malaysia’s adherence to green manufacturing practices gives it an edge over Indonesia, which is still developing in this area.

5. How Malaysia Competes with the Philippines

Philippines’ Strengths

The Philippines is known for its growing electronics industry, which drives demand for metal components. Its English-speaking workforce and proximity to the USA also make it a favorable destination for exports.

Malaysia’s Competitive Edge

- More Developed Infrastructure: Malaysia’s ports, road networks, and industrial parks are more advanced, facilitating efficient production and export logistics.

- Diverse Export Portfolio: While the Philippines focuses on a few key industries, Malaysia caters to a broader range of sectors, including aerospace, automotive, and construction.

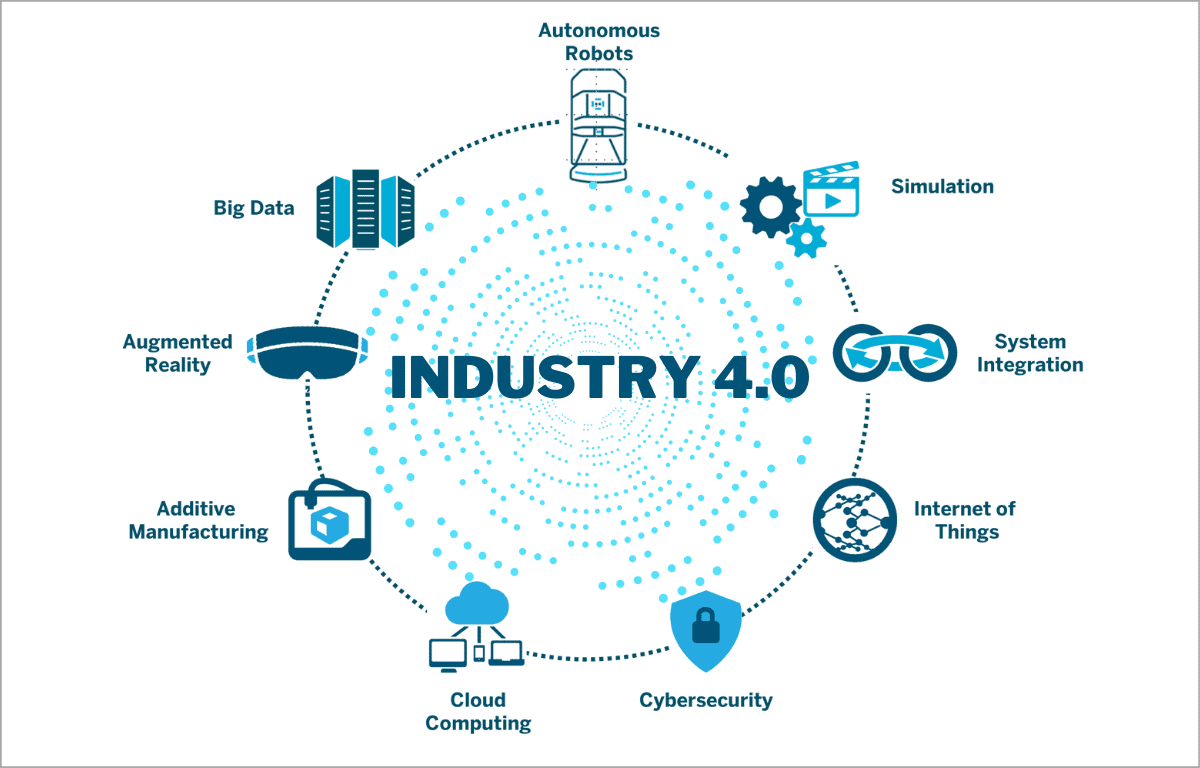

- Technological Investment: Malaysia’s commitment to Industry 4.0 technologies enhances its competitiveness in high-precision metalworking.

6. Malaysia’s Focus on High-Value Industries

Malaysia competes effectively by targeting high-value industries that demand precision and quality, such as:

Aerospace

Malaysia is a key supplier of precision metal components for aerospace giants like Boeing and Airbus. The industry requires metals with extreme durability and high precision, areas where Malaysia excels.

Medical Devices

The precision required for medical instruments and implants makes Malaysia a preferred exporter for this sector.

Automotive

Malaysia produces high-quality automotive components, particularly for electric vehicles (EVs), leveraging its technological expertise.

Electronics

Penang, often referred to as the Silicon Valley of the East, houses companies that require precision metal components for electronics manufacturing.

7. Challenges Malaysia Faces in Competing with Southeast Asian Countries

Despite its strengths, Malaysia faces several challenges:

- Rising Costs: Labor and operational costs in Malaysia are higher than in Vietnam and Indonesia, making it less competitive for low-cost, high-volume manufacturing.

- Limited Domestic Raw Materials: Unlike Indonesia, Malaysia relies on imports for some raw materials, which increases production costs.

- Competition in Trade Agreements: Vietnam’s FTAs with major markets like the EU provide it with tariff advantages over Malaysia.

8. Malaysia’s Strategies to Stay Competitive

To remain competitive in the export of metal sheets and precision metal products, Malaysia adopts the following strategies:

1. Invest in Industry 4.0

The Malaysian government encourages industries to adopt advanced technologies, including automation, AI, and IoT, through initiatives like the Industry4WRD policy.

Reference: What is Industry 4.0?

2. Strengthen Trade Agreements

Malaysia actively engages in regional and global trade agreements, such as:

- RCEP (Regional Comprehensive Economic Partnership).

- Comprehensive and Progressive Agreement for Trans-Pacific Partnership (CPTPP).

3. Focus on Sustainability

By adhering to green manufacturing practices and environmental certifications, Malaysia appeals to Western markets that prioritize sustainability.

4. Enhance Workforce Skills

Ongoing investments in TVET and technical universities ensure a steady pipeline of skilled workers for high-precision industries.

5. Promote Value-Added Products

Malaysia emphasizes the production of finished and precision metal products rather than raw materials, allowing it to capture higher margins and cater to niche markets.

Conclusion

Malaysia competes fiercely with Southeast Asian neighbors in the metal sheet and precision metal export markets by leveraging its advanced manufacturing capabilities, focus on high-value industries, and commitment to quality and innovation. While challenges like rising costs and competition from Vietnam and Indonesia exist, Malaysia’s strategic initiatives and robust industrial base position it as a leader in the region’s metal export sector.

As global demand for precision and high-quality metal products grows, Malaysia’s ability to adapt to market needs and embrace technological advancements ensures its continued success on the world

For all your metal fabrication needs, visit Lux Metal Group for customized solutions and state-of-the-art services.

LUX METAL is a steel manufacturer in Malaysia, we speciliazed in customized metal solutions according to your DIY requirements.

We provide a comprehensive range of stainless steel fabrication works, tailored to meet the diverse needs of our clients. Our state-of-the-art facility is equipped with all kinds of advanced machinery, including CNC machines and precision equipment, enabling us to handle projects of any scale and complexity with the utmost accuracy. Our expertise spans various industries, ensuring that every project is executed with precision and excellence.

We have comprehensive range of machineries to handle your projects including Laser Cutting Machine, Bending Machine, Milling Machine, Sheet Bending Machine, Sheet Rolling Machine, TUrning Machine, Welding Machine, Laser Marking Machine, V-Cutting Machine, Wire Cut Machine, and etc.