1. Integration of Advanced Construction Technologies

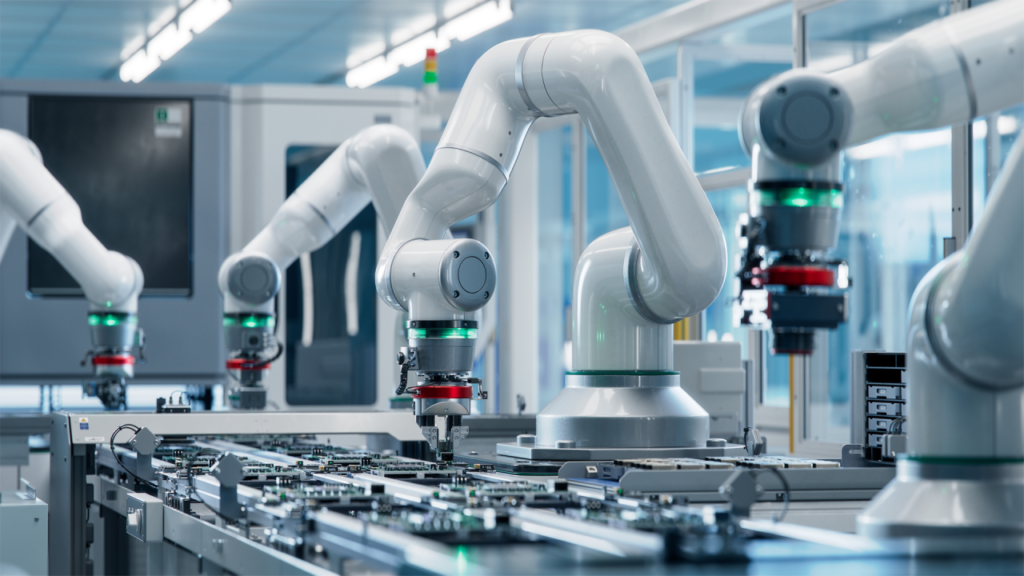

Technological innovations such as robotics, drones, and 3D printing are revolutionizing construction sites, enhancing efficiency, and reducing costs.

- Building Information Modeling (BIM): BIM is no longer optional but a standard tool for collaborative design and planning. It offers enhanced project visualization and reduces errors during construction.

- Artificial Intelligence (AI): AI is being increasingly used for predictive analytics, risk management, and optimizing workflows, leading to smarter project management.

- Drones streamline tasks like site surveys, progress monitoring, and aerial imaging, providing real-time insights and improved accuracy.

- Robotics automate repetitive tasks such as bricklaying, freeing skilled workers to focus on complex aspects of construction.

- 3D Printing drastically reduces material waste, labor expenses, and build times, offering sustainable and flexible solutions.

For example, 3D-printed residential buildings can lower costs by up to 45%, making them a game-changer for affordable housing projects. Subcontractors adopting these technologies can boost productivity and gain a competitive edge in the market.

2. Modular and Prefabricated Construction

Prefabrication and modular construction are gaining popularity due to their efficiency and quality benefits. Components are manufactured off-site in controlled environments, then assembled on-site, reducing project timelines and ensuring consistent quality.

- Fewer Delays: Reduced on-site construction time minimizes weather-related disruptions.

- Improved Quality: Controlled manufacturing environments enhance precision and reliability.

Subcontractors can benefit by partnering with prefabrication specialists or incorporating these methods into their workflow, enabling them to tackle more projects with greater efficiency.

3. Emphasis on Sustainable Construction Practices

Sustainability is no longer optional—it’s a cornerstone of modern construction. Clients demand environmentally friendly solutions, and subcontractors must adapt to meet these expectations.

- Green Materials: Use recycled steel, bamboo, or eco-friendly concrete to reduce environmental impact.

- Energy Efficiency: Incorporate renewable energy systems like solar panels.

- Certifications: Obtain LEED or similar eco-certifications to showcase your commitment to sustainability.

Additionally, consider using electric or remanufactured equipment, which reduces energy consumption by up to 80% compared to manufacturing new machinery. Renting machinery is another sustainable trend, projected to reach a $181.81 billion market size by 2031, offering cost-effective and eco-friendly alternatives.

4. Data-Driven Project Management

Real-time data and construction management software are transforming how projects are planned and executed.

- Transparency: Track project budgets, schedules, and materials in real-time.

- Efficiency: Identify bottlenecks and resolve issues promptly.

- Collaboration: Improve communication between teams, clients, and stakeholders.

These tools empower subcontractors to make informed decisions, prevent cost overruns, and deliver high-quality projects on time and within budget.

5. Stronger Focus on Health and Safety

With stricter regulations and a growing emphasis on worker safety, the construction industry is adopting innovative technologies to create safer job sites.

- Wearables: Smart helmets, vests, and sensors monitor worker health and site conditions.

- Compliance: Stay updated on the latest safety standards to avoid penalties and ensure worker well-being.

By investing in advanced safety measures, subcontractors can build trust with clients and protect their workforce while enhancing overall project efficiency.

6. Addressing Labor Shortages

The construction industry faces a severe labor shortage, with over 500,000 additional workers needed to meet demand. Subcontractors must find creative solutions to overcome this challenge.

- Upskilling: Provide specialized training to your workforce to boost productivity and fill skill gaps.

- Automation: Implement automated tools to streamline repetitive tasks and increase efficiency.

- Partnerships: Collaborate with educational institutions to access a pool of newly trained workers.

These strategies ensure your team remains competitive and capable of handling complex projects despite labor market constraints.

7. Navigating Supply Chain Challenges

Supply chain disruptions continue to impact material availability and costs. For instance, prices for wood, plastics, and thermal protection materials may rise by up to 6.5% annually until 2025.

- Bulk Purchasing: Secure materials in advance when prices are lower.

- Alternative Suppliers: Diversify your supplier base to avoid dependency on a single source.

- Strong Relationships: Build partnerships with suppliers for priority access to materials during shortages.

Staying agile in the face of supply chain challenges ensures your projects remain on schedule and within budget.

8. Adoption of Smart Building Technologies

Smart buildings equipped with IoT (Internet of Things) devices are redefining construction and facility management.

- Energy Management: Use smart sensors to monitor and optimize energy usage.

- Automation: Implement intelligent systems for lighting, heating, and cooling.

- Maintenance: Leverage predictive analytics to reduce downtime and extend the lifespan of building systems.

Subcontractors who embrace smart technologies can offer clients innovative solutions that enhance building performance and sustainability.

9. Focus on Resilient Infrastructure

As climate change intensifies, the demand for resilient infrastructure is growing.

- Durable Materials: Use weather-resistant and sustainable materials for long-lasting structures.

- Flood Prevention: Incorporate drainage systems and elevated designs in flood-prone areas.

- Energy Independence: Integrate renewable energy systems to create self-sustaining buildings.

By prioritizing resilience, subcontractors can address client concerns about environmental risks and deliver structures built to last.

10. Rise of Construction-as-a-Service (CaaS)

The CaaS model is reshaping the industry by offering clients subscription-based access to construction services.

- Flexibility: Provide tailored solutions based on client needs.

- Cost-Effectiveness: Reduce upfront costs for clients by spreading payments over time.

- Innovation: Use advanced tools and methods to deliver exceptional results.

Adopting the CaaS model allows subcontractors to meet evolving client demands while generating steady revenue streams.

Stay Ahead of the Curve with Lux Metal

The construction industry is entering an exciting era of innovation and opportunity. By embracing these trends, you can position yourself as a leader and deliver unparalleled value to your clients.

At Lux Metal Group, we specialize in providing high-quality custom metal solutions to support your construction projects. From sustainable materials to precision engineering, we’re here to help you stay ahead in this dynamic industry.

Learn more about how we can transform your projects. Visit Lux Metal Group today!

For further insights, explore: