What Is Stainless Steel Printing?

Stainless steel printing refers to the process of applying a design, text, or image onto a stainless steel surface. The printing can serve various purposes, such as decorative, informative, or functional. Each technique involves specific machinery, inks, and processes to ensure that the print adheres well to the metal surface and remains durable over time.

Types of Stainless Steel Printing Techniques

There are several methods for printing on stainless steel, each offering unique benefits depending on the project’s requirements.

1. Screen Printing

Screen printing is a versatile technique that uses a mesh to transfer ink onto the stainless steel surface. This method is best for simple designs and text, often used for larger prints. The process allows for a thick layer of ink to adhere to the surface, making it ideal for bold and colorful designs. However, the level of detail can be limited.

2. Pad Printing

Pad printing involves transferring ink from a silicone pad onto the stainless steel. This method is excellent for printing on irregularly shaped surfaces or fine details that may not be achievable through screen printing. Pad printing is commonly used for labeling small parts or intricate designs.

3. Flexographic Printing

Flexographic printing uses flexible plates made of rubber or plastic to print on stainless steel. This technique is popular for large-scale printing applications because it offers high-speed production and works well with various types of inks. Flexographic printing is widely used in the packaging industry and for printing on cylindrical stainless steel products.

4. Dye Sublimation

Dye sublimation printing works by transferring ink onto a special coating on the stainless steel surface via heat. This method is particularly effective for full-color designs and images, as it allows for high-resolution prints. The downside is that the stainless steel needs to be pre-treated with a polymer coating to make it compatible with this method.

5. Inkjet Printing

Inkjet printing uses droplets of ink to form images or text on stainless steel. It’s ideal for producing high-quality, intricate details and can work with various types of inks, including UV-cured and water-based inks. Inkjet printing is often employed for custom projects requiring precision.

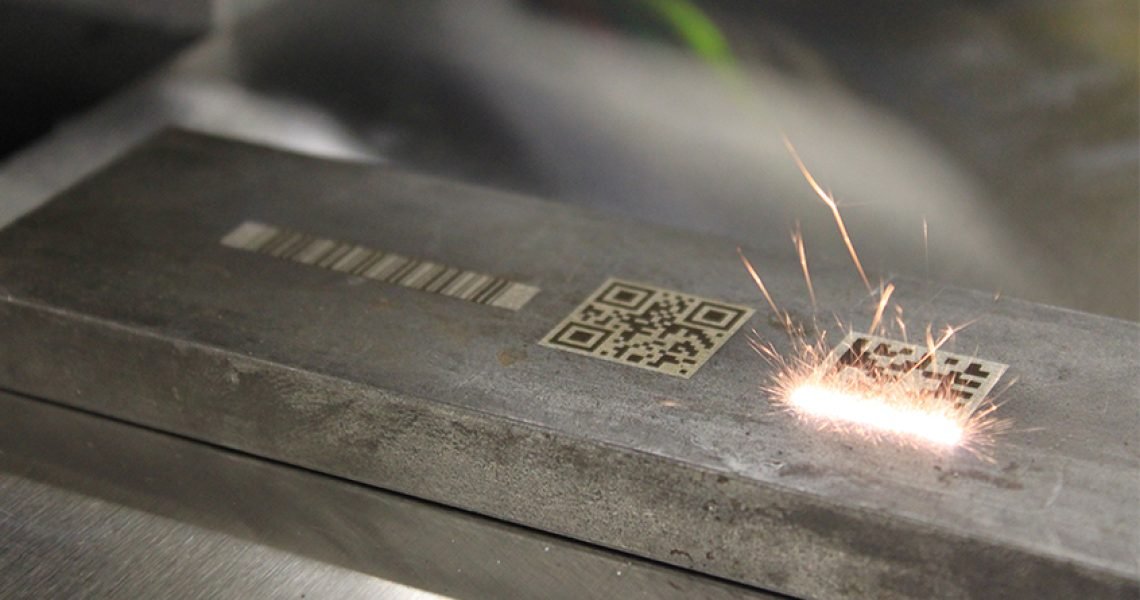

6. Laser Marking

Laser marking uses a focused laser beam to either etch or engrave designs into the stainless steel surface. There are four primary types of laser marking techniques:

- Laser Engraving: This process physically removes part of the material to create deep, long-lasting marks.

- Laser Annealing: A process that changes the color of the steel without removing any material. It’s often used for medical instruments and tools.

- Laser Etching: Creates a slight surface mark that is less deep than engraving but still durable.

- Laser Foaming: Produces raised marks on the surface by creating bubbles in the material.

7. Chemical and Electrochemical Etching

In chemical etching, the surface of the stainless steel is exposed to chemicals that remove material in specific areas, creating a design. Electrochemical etching, on the other hand, uses an electrical current to achieve a similar effect. Both methods are precise and excellent for permanent designs but may require more complex setup processes.

Inks Used in Stainless Steel Printing

The type of ink used in stainless steel printing is crucial, as it must be able to adhere well to the surface and withstand the conditions to which the product will be exposed. Below are the most common types of inks used:

1. Epoxy Inks

Epoxy inks are known for their excellent adhesion to non-porous surfaces like stainless steel. They provide good resistance to chemicals and weather conditions, making them ideal for industrial applications.

2. UV-Curable Inks

UV-curable inks harden upon exposure to ultraviolet light, resulting in a durable finish that resists scratches and fading. This type of ink is perfect for applications where the print must endure exposure to the elements or frequent handling.

3. Solvent-Based Inks

Solvent-based inks contain volatile organic compounds (VOCs) that evaporate, leaving behind a durable print. These inks are favored for their strong adhesion and long-lasting nature, but they may require proper ventilation during application due to the emissions produced.

4. Water-Based Inks

Water-based inks are eco-friendly alternatives to solvent-based inks. While they may not offer the same level of durability, they are ideal for applications where environmental impact is a concern.

5. Ceramic Inks

Ceramic inks are specialized for use on stainless steel surfaces that need to withstand extreme conditions, such as high heat or abrasion. These inks are often used for decorative purposes, especially in the production of appliances and fixtures.

Pre-Treatment and Post-Treatment in Stainless Steel Printing

Proper pre-treatment and post-treatment processes are vital for ensuring the quality and longevity of printed designs on stainless steel.

Pre-treating Stainless Steel for Printing

Before printing, the stainless steel surface must be thoroughly cleaned to remove contaminants like oil, dust, or rust. Some printing methods, like dye sublimation, also require a special coating to make the surface compatible with the ink.

Post-Treatment of Printed Stainless Steel

Post-treatment typically involves curing the printed design using heat or UV light, depending on the type of ink used. In some cases, an additional protective coating may be applied to enhance durability, particularly for items exposed to harsh environments.

Characteristics of Printed Stainless Steel

Stainless steel printing provides unique characteristics that make it a preferred choice across industries:

1. Durability

Printed designs on stainless steel can last for years without fading or wearing, especially when treated with protective coatings.

2. Toxicity

Stainless steel printing is often non-toxic, especially when using eco-friendly inks like water-based or ceramic inks, making it safe for applications in the food and medical industries.

3. Cost-Effectiveness

Although some printing techniques may involve higher initial setup costs, stainless steel printing is generally cost-effective, especially for large-scale production.

The Uses of Stainless Steel Printing

Stainless steel printing is versatile and used across various industries. Common applications include:

- Branding: Logos and product information are printed on stainless steel items like kitchen appliances and tools.

- Signage: Stainless steel signage is durable and suitable for both indoor and outdoor environments.

- Medical Equipment: Laser marking is commonly used to label surgical instruments and medical devices.

- Automotive Industry: Various components in vehicles are labeled or decorated using stainless steel printing techniques.

Challenges of Stainless Steel Printing

While stainless steel printing offers many advantages, it is not without challenges.

1. Material Compatibility Issues

Some printing techniques, such as dye sublimation, require pre-treatment with special coatings, adding complexity to the process.

2. Difficulty in Printing Fine Details

Techniques like screen printing may struggle to reproduce intricate designs with fine details, requiring alternative methods like inkjet or laser marking.

3. Limited Color Options

While stainless steel printing is durable, it can be limited in terms of color vibrancy, especially compared to traditional paper or fabric printing.

Conclusion

Stainless steel printing offers a wide array of possibilities for industries seeking durable, high-quality, and visually appealing results. From intricate designs to robust industrial applications, the right printing technique and inks can make all the difference in achieving long-lasting, precise outcomes. Whether you’re looking to enhance branding, create durable signage, or add personalized touches to your products, mastering the right stainless steel printing methods is essential.

If you’re ready to take your stainless steel projects to the next level, explore our advanced solutions at LUX Metal. Our state-of-the-art equipment and expert team can help you achieve the perfect results for any application. Visit us today to learn more about our stainless steel customization services.

References

For further reading, check out these comprehensive guides: