Understanding Stainless Steel

Stainless steel is a metal alloy that contains a minimum of 10.5% chromium. This chromium content is what gives stainless steel its impressive corrosion resistance. The chromium reacts with oxygen in the environment to form a thin, stable layer of chromium oxide on the surface of the steel. This layer acts as a protective barrier, preventing rust and corrosion from penetrating the metal.

Advantages of Stainless Steel:

- High Corrosion Resistance: Stainless steel is well-known for its ability to resist rust and corrosion, even in harsh environments like coastal areas or industrial settings.

- Aesthetic Appeal: With its sleek, polished finish, stainless steel is often chosen for applications where appearance matters, such as in architectural projects and high-end kitchen appliances.

- Strength and Durability: Stainless steel retains its structural integrity under extreme temperatures and heavy loads, making it ideal for demanding applications.

- Hygienic Properties: Stainless steel is non-porous and easy to clean, making it a preferred material in the food and beverage industry, as well as in medical applications.

Common Applications of Stainless Steel:

- Construction: Used in building facades, structural components, and reinforcing bars.

- Automotive: Commonly found in exhaust systems, trim, and fasteners.

- Medical Equipment: Preferred for surgical instruments, implants, and hospital equipment due to its hygienic properties.

- Food Processing: Used in equipment like tanks, pipes, and conveyors, where hygiene and corrosion resistance are critical

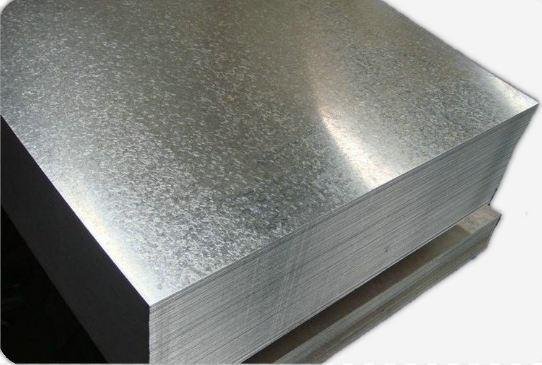

What is Galvanized Steel?

Galvanized steel is simply steel that has been coated with a layer of zinc to protect it from rust and corrosion. The zinc acts as a barrier that prevents corrosive substances from reaching the steel, thereby significantly extending its lifespan. The process of galvanization can be done in various ways, but the most common methods are hot-dip galvanizing and electro-galvanizing.

The Galvanization Process: How Galvanized Steel is Made

The galvanization process is crucial in ensuring the steel is well-protected against corrosion. There are two primary methods used to galvanize steel: hot-dip galvanizing and electro-galvanizing.

Hot-Dip Galvanizing:

- Process: Hot-dip galvanizing involves dipping steel into a bath of molten zinc, heated to around 450°C (842°F). The steel is fully submerged in the zinc, allowing the zinc to bond with the steel and form a thick, durable coating.

- Advantages: This method provides a robust layer of zinc that can withstand significant wear and tear. The zinc coating also protects the steel from minor damages, as any exposed steel will be covered by the surrounding zinc, which prevents rust from forming.

- Result: The finished product has a matte gray appearance, often seen in many construction and industrial applications. The thick coating ensures long-lasting protection, making it ideal for outdoor and heavy-duty uses.

Electro-Galvanizing:

- Process: In electro-galvanizing, a thin layer of zinc is applied to the steel through an electrochemical process. This involves passing an electric current through a solution of zinc ions, which causes the zinc to adhere to the surface of the steel.

- Advantages: This method allows for a more controlled application of zinc, resulting in a smoother finish. Electro-galvanized steel is often used in applications where precision and a uniform coating are necessary.

- Result: The zinc layer is thinner compared to hot-dip galvanizing, making it suitable for applications where a high level of corrosion resistance is not required, but a smooth, clean finish is desirable.

Key Benefits of Galvanized Steel

Galvanized steel offers a range of benefits that make it a popular choice across various industries:

- Superior Corrosion Resistance: The zinc coating on galvanized steel provides excellent protection against rust and corrosion, especially in environments exposed to moisture. This makes galvanized steel ideal for outdoor applications where other types of steel might degrade more quickly.

- Long Lifespan: Galvanized steel is designed to last, with a lifespan that can exceed several decades, even in harsh environments. This durability translates to reduced maintenance costs over time, as the steel does not need to be replaced or treated as frequently as other materials.

- Cost-Effective Solution: Compared to other corrosion-resistant materials like stainless steel, galvanized steel is more affordable. The initial investment in galvanized steel is often lower, and the reduced maintenance costs make it an economical choice in the long run.

- Ease of Inspection: The condition of the zinc coating on galvanized steel can be easily assessed visually. This allows for quick and straightforward inspections, ensuring that the steel is still adequately protected.

- Versatility: Galvanized steel can be used in a wide variety of applications, from large-scale construction projects to small components in manufacturing. Its versatility makes it a go-to material for many engineers and designers

Common Applications of Galvanized Steel

Due to its durability and resistance to corrosion, galvanized steel is used in a broad range of applications:

- Construction: Galvanized steel is a staple in the construction industry, used for building frames, roofing, and structural beams. Its ability to resist corrosion makes it particularly useful for outdoor structures exposed to the elements.

- Automotive Industry: Many automotive parts, such as the body panels, chassis, and underbody components, are made from galvanized steel. The zinc coating helps protect these parts from rust and prolongs the lifespan of the vehicle.

- Home Appliances: Household appliances like refrigerators, washing machines, and HVAC systems often incorporate galvanized steel components. The corrosion resistance ensures these appliances maintain their functionality over time, even when exposed to moisture.

- Agriculture: In agricultural settings, galvanized steel is used for silos, barns, and other structures that need to withstand exposure to moisture and other corrosive elements. It is also used in fencing and other outdoor applications where long-term durability is essential.

- Infrastructure: Galvanized steel is integral to the construction of infrastructure such as bridges, highways, and power transmission towers. Its ability to withstand environmental factors and its structural strength make it an ideal material for these critical applications.

Considerations When Using Galvanized Steel

While galvanized steel is an excellent material for many uses, there are some considerations to keep in mind:

- Thickness of Coating: The thickness of the zinc coating can vary depending on the method of galvanization and the intended application. Thicker coatings provide better protection but may increase the cost and weight of the material.

- Environmental Factors: Galvanized steel performs well in most environments but may not be suitable for extremely corrosive conditions, such as those found in marine environments or heavy industrial areas. In such cases, additional protective measures or alternative materials may be required.

- Welding and Painting: Although galvanized steel can be welded and painted, the zinc coating can make these processes more challenging. Special techniques are needed to avoid damaging the coating and to ensure a strong bond.

Choosing the Right Material for Your Project

When selecting between stainless steel and galvanized steel, consider the specific requirements of your project. If your project demands superior corrosion resistance, strength, and aesthetic appeal, stainless steel is likely the better choice. However, if cost-effectiveness and good corrosion resistance in less harsh environments are your primary concerns, galvanized steel may be more suitable.

For more detailed information, you can explore the original resource at Xometry’s Galvanized Steel Guide and Tuolian Metal’s Stainless Steel vs. Galvanized Steel Comparison.

Conclusion

Choosing between stainless steel and galvanized steel depends on the specific needs of your project. Both materials offer distinct advantages, whether it’s the exceptional corrosion resistance of stainless steel or the cost-effective durability of galvanized steel. Making the right choice will not only enhance the performance of your construction projects but also ensure long-term success.

For custom stainless steel solutions that are tailored to your exact specifications, trust the expertise of Lux Metal Group. We are dedicated to providing high-quality materials and precision-engineered products to support your construction needs. Visit Lux Metal Group today to discover how we can help you build with strength, style, and excellence.