What is Stainless Steel?

Composition and Properties

Stainless steel is an iron-based alloy containing at least 10.5% chromium. This chromium content forms a thin protective oxide layer on the steel’s surface, making it highly resistant to rust and corrosion. Other alloying elements, such as nickel, molybdenum, and titanium, may be added to enhance its strength, heat resistance, and durability.

Key Characteristics of Stainless Steel

- High Corrosion Resistance: The chromium content creates a protective layer that prevents oxidation and rust, making it ideal for environments exposed to moisture or chemicals.

- Strength and Durability: Stainless steel is stronger than mild steel, offering excellent resistance to wear and impact.

- Aesthetic Appeal: It has a smooth, polished finish that makes it suitable for decorative applications.

- Hygienic and Easy to Clean: Its non-porous surface prevents bacterial growth, making it ideal for medical, food processing, and kitchen applications.

- Heat and Fire Resistance: Stainless steel can withstand high temperatures, making it suitable for exhaust systems, heat exchangers, and other heat-exposed environments.

Common Types of Stainless Steel

Stainless steel is available in different grades, each suited for specific applications:

- 304 Stainless Steel – The most commonly used grade, offering excellent corrosion resistance and durability.

- 316 Stainless Steel – Contains molybdenum, making it more resistant to saltwater and harsh chemicals (often used in marine applications).

- 430 Stainless Steel – A cost-effective option with moderate corrosion resistance, typically used for decorative applications.

What is Mild Steel?

Composition and Properties

Mild steel, also known as low-carbon steel, contains 0.05% to 0.25% carbon and lacks significant alloying elements like chromium or nickel. This makes it softer, more malleable, and easier to work with compared to stainless steel.

Key Characteristics of Mild Steel

- High Ductility and Malleability: Mild steel is easy to cut, bend, and weld, making it highly suitable for fabrication and construction.

- Cost-Effective: One of the main advantages of mild steel is its affordability, as it is significantly cheaper than stainless steel.

- Good Tensile Strength: While not as strong as stainless steel, mild steel still provides adequate strength for most structural applications.

- Magnetic Properties: Due to its iron content, mild steel is magnetic, which can be beneficial in certain industrial applications.

Common Types of Mild Steel

- Cold Rolled Mild Steel – Processed at room temperature for a smooth finish and higher strength.

- Hot Rolled Mild Steel – Processed at high temperatures, making it easier to form but resulting in a rougher surface.

- Galvanized Mild Steel – Coated with zinc to improve corrosion resistance and longevity.

Key Differences: Stainless Steel vs. Mild Steel

| Factor | Stainless Steel | Mild Steel |

|---|---|---|

| Composition | Contains chromium (10.5%+), nickel, and other alloys | Contains iron and a small percentage of carbon |

| Corrosion Resistance | Highly resistant to rust and corrosion | Prone to rust unless coated (e.g., galvanized) |

| Strength & Hardness | Stronger, more durable, and resistant to wear | Softer and more malleable |

| Cost | More expensive due to alloying elements | More affordable and widely available |

| Aesthetic Appeal | Smooth, polished finish, suitable for decorative use | Dull appearance, often painted or coated |

| Maintenance | Low maintenance, easy to clean | Requires regular maintenance to prevent rust |

| Weldability | More challenging to weld due to high strength | Easier to weld and fabricate |

| Magnetism | Non-magnetic (except some grades) | Magnetic |

| Heat Resistance | Withstands high temperatures | Lower heat resistance compared to stainless steel |

| Lifespan | Long lifespan with minimal maintenance | Shorter lifespan unless properly treated |

Applications: Where is Each Steel Type Used?

Common Uses of Stainless Steel

Stainless steel is the preferred choice for applications requiring corrosion resistance, strength, and aesthetic appeal.

- Construction and Architecture: Used for handrails, cladding, roofing, and decorative features.

- Medical and Food Industry: Ideal for surgical tools, food processing equipment, and kitchen sinks due to its hygienic properties.

- Marine and Coastal Applications: Used in boats, docks, and offshore structures because of its resistance to saltwater corrosion.

- High-Temperature Environments: Found in exhaust systems, furnaces, and heat exchangers due to its ability to withstand extreme heat.

- Luxury and Design: Used in furniture, home decor, and high-end appliances for its sleek appearance.

Common Uses of Mild Steel

Mild steel is widely used in structural, industrial, and automotive applications where cost and ease of fabrication are primary concerns.

- Structural Engineering: Used in buildings, bridges, and infrastructure due to its strength and affordability.

- Automobile and Machinery Manufacturing: Preferred for vehicle frames, chassis, and machine components.

- Piping and Tubing: Used for water pipes, gas pipelines, and construction tubing.

- Gates, Grills, and Fencing: Common in security applications due to its weldability and strength.

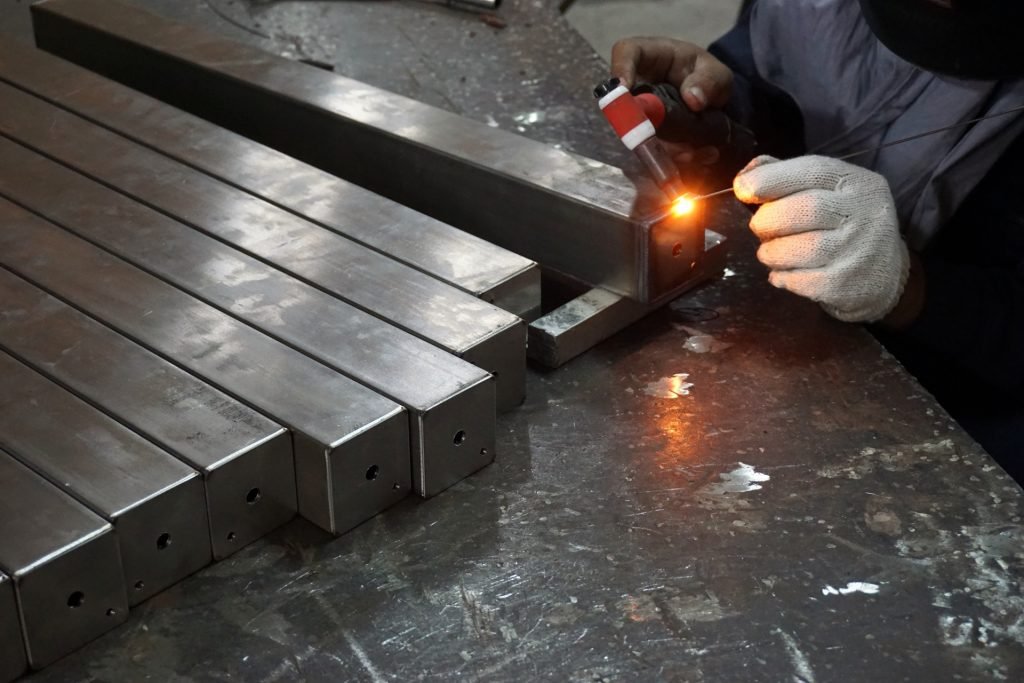

- Fabrication and Manufacturing: Easier to weld and shape, making it ideal for custom fabrication projects.

Examples of Appliances and Products Made from Stainless Steel and Mild Steel

Both stainless steel and mild steel are widely used in various industries, each serving different purposes based on their properties. Below are some common applications and real-world products made from each type of steel.

Appliances and Products Made from Stainless Steel

1. Kitchen and Household Appliances

- Refrigerators – Many modern refrigerators have stainless steel doors and interiors for durability and a sleek appearance.

- Ovens and Stovetops – Heat-resistant stainless steel is used for gas ranges, oven interiors, and cooktops.

- Dishwashers – Stainless steel interiors provide rust resistance and prevent bacterial buildup.

- Kitchen Sinks and Faucets – Corrosion-resistant stainless steel is the top choice for kitchen sinks.

- Cookware and Utensils – High-quality pots, pans, knives, and spoons are made from stainless steel for hygiene and durability.

2. Medical and Healthcare Equipment

- Surgical Instruments – Scalpels, forceps, and scissors are made of stainless steel for sterilization purposes.

- Hospital Beds and Furniture – Used in operating tables, stretchers, and hospital carts due to easy cleaning and resistance to bacteria.

- Medical Implants – Stainless steel is used in artificial joints, dental implants, and orthopedic screws.

3. Industrial and Engineering Applications

- Pipelines and Tanks – Used in the food, chemical, and pharmaceutical industries due to its resistance to corrosion and contamination.

- Heat Exchangers and Boilers – Withstands high temperatures and exposure to chemicals in industrial plants.

- Automotive and Aerospace Parts – High-end car exhaust systems, aircraft structural components, and fuel tanks are often made of stainless steel.

4. Construction and Architecture

- Handrails and Balustrades – Common in modern buildings for aesthetic appeal and durability.

- Cladding and Roofing Panels – Used in high-rise buildings and stadiums due to its long lifespan.

- Elevators and Escalators – Provides strength and a polished finish.

5. Marine and Coastal Equipment

- Boat Railings and Fittings – Stainless steel resists saltwater corrosion, making it ideal for marine applications.

- Fishing Equipment – Hooks, nets, and commercial fish processing machines often use stainless steel.

Appliances and Products Made from Mild Steel

1. Construction and Infrastructure

- Building Frames and Beams – Mild steel is used in the construction of bridges, warehouses, and skyscrapers.

- Rebar (Reinforcing Steel Bars) – Used to strengthen concrete structures in buildings and roads.

- Fencing and Gates – Mild steel provides strength and can be coated for rust protection.

2. Automotive and Transportation

- Car Chassis and Frames – Mild steel is widely used in vehicle manufacturing due to its affordability.

- Railway Tracks and Train Cars – The railway industry uses mild steel for its durability and strength.

- Shipbuilding – Hulls of ships and barges are made from mild steel, coated to prevent rust.

3. Manufacturing and Fabrication

- Machinery and Equipment Frames – Industrial machines and conveyor systems use mild steel for structural support.

- Storage Racks and Shelving – Used in warehouses and factories for heavy-duty storage.

- Scaffolding and Ladders – Mild steel is commonly used in construction scaffolding due to its strength.

4. Household and Decorative Uses

- Furniture Frames – Tables, chairs, and bed frames often use mild steel for support.

- Outdoor Grills and Fire Pits – Mild steel is used for barbecue grills and fire pits due to its ability to handle high temperatures.

- Light Poles and Street Signs – Found in urban areas and highways, coated to prevent rust.

5. Agricultural and Farming Equipment

- Tractor Frames and Plows – Mild steel is used in farming tools and machinery.

- Irrigation Systems – Pipes and storage tanks for agricultural use.

- Storage Silos – Used for storing grains and animal feed.

Which One Should You Choose?

When to Choose Stainless Steel:

✅ If corrosion resistance is crucial (e.g., marine, food, medical industries)

✅ When you need high strength and durability

✅ If hygiene and cleanliness are priorities (e.g., medical or food-related applications)

✅ If you require heat resistance

When to Choose Mild Steel:

✅ If cost-effectiveness is a priority

✅ For projects that require extensive welding and machining

✅ When working on large structures where affordability is important

✅ If corrosion can be managed using protective coatings or treatments

Final Thoughts

Both stainless steel and mild steel are valuable materials with their own distinct advantages. While stainless steel excels in corrosion resistance, strength, and heat resistance, mild steel is more cost-effective, easy to work with, and widely available. The choice ultimately depends on the specific needs of your project, the environmental conditions, and budget constraints.

When making your decision, consider long-term maintenance costs, durability, and the required performance to ensure you choose the right steel for your application. If you need expert advice or high-quality stainless steel fabrication services, feel free to contact Lux Metal today for the best solutions tailored to your needs.

Lux Metal – Your Trusted Partner in Customized Metal Fabrication

At Lux Metal, we specialize in high-quality stainless steel fabrication tailored to your needs. Our expertise includes:

✅ Precision Laser Cutting

✅ Sheet Bending & Rolling

✅ CNC Machining

✅ Custom Metal Fabrication

Whether you need customized stainless steel solutions for construction, industrial applications, or manufacturing, Lux Metal is here to deliver top-notch quality and reliability.

👉 Visit us at Lux Metal to explore our services!