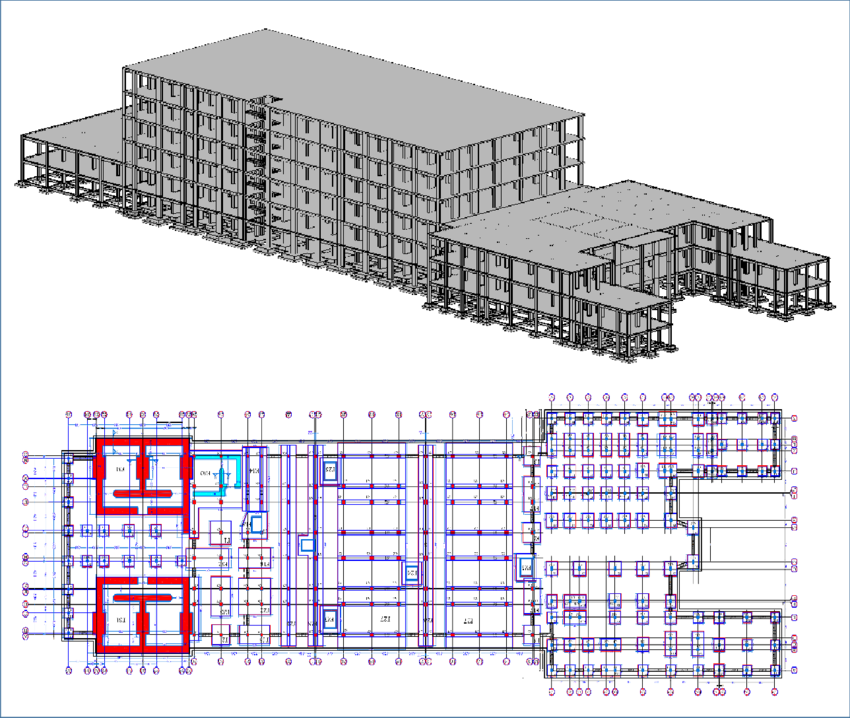

What Are 2D CAD Drawings in Construction?

2D CAD (Computer-Aided Design) drawings are digital representations of a construction project created using specialized software. These drawings are two-dimensional, meaning they display only the height and length of a structure on a flat plane, without depth.

In construction, 2D CAD drawings are widely used for creating:

- Blueprints and Floor Plans: Essential for project planning and layout.

- Construction Details: Showcasing specific sections or components.

- Site Plans: Depicting the arrangement of structures on the site.

These drawings are an industry standard for communicating concepts, detailing materials, and ensuring precision in project execution. The simplicity and clarity of 2D designs make them easy to understand for a broad audience, including clients, contractors, and workers on-site.

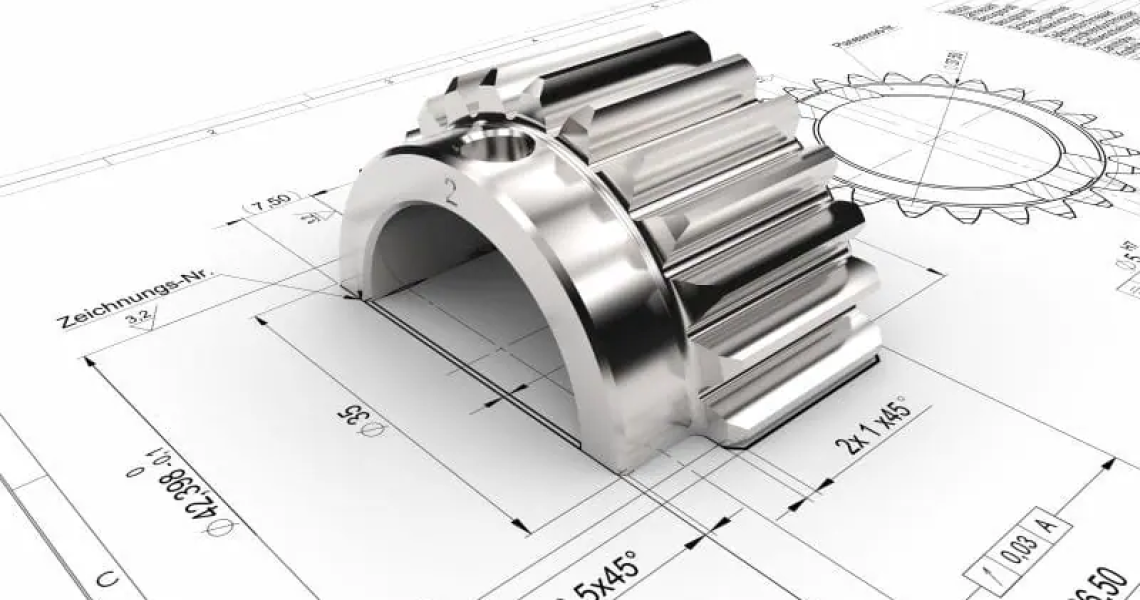

Understanding 2D CAD Drawings in Metal Fabrication and Manufacturing

2D CAD drawings are two-dimensional digital designs used to create accurate and detailed blueprints of metal parts, components, and assemblies. These drawings focus on displaying length and height, providing essential views such as top, side, and front profiles.

In the metal fabrication and manufacturing industry, 2D CAD drawings are critical for:

- Production Blueprints: These are detailed technical sheets that outline the dimensions, materials, and tolerances required for manufacturing a part or product.

- Laser Cutting and Machining: 2D drawings are directly converted into machine-readable formats for processes like CNC machining, laser cutting, and sheet metal bending.

- Simplifying Communication: Clear and standardized drawings make it easier for engineers, machinists, and operators to understand the requirements without ambiguity.

These drawings are lightweight, easy to share, and simple to print, making them ideal for factory floors, where quick access to clear instructions is crucial.

What Are 3D Models in Construction?

3D models, on the other hand, are three-dimensional digital designs that display the width, height, and depth of a structure. Created using advanced CAD software, 3D models provide a realistic, life-like representation of a construction project.

Key applications of 3D models in construction include:

- Conceptual Visualization: Allowing clients to see a realistic depiction of the finished structure.

- Detailed Design: Including complex systems like HVAC, plumbing, and electrical networks.

- Clash Detection: Identifying and resolving design conflicts before construction begins.

With 3D models, construction teams can simulate real-world scenarios, test structural integrity, and identify potential design flaws, offering a higher level of precision and innovation.

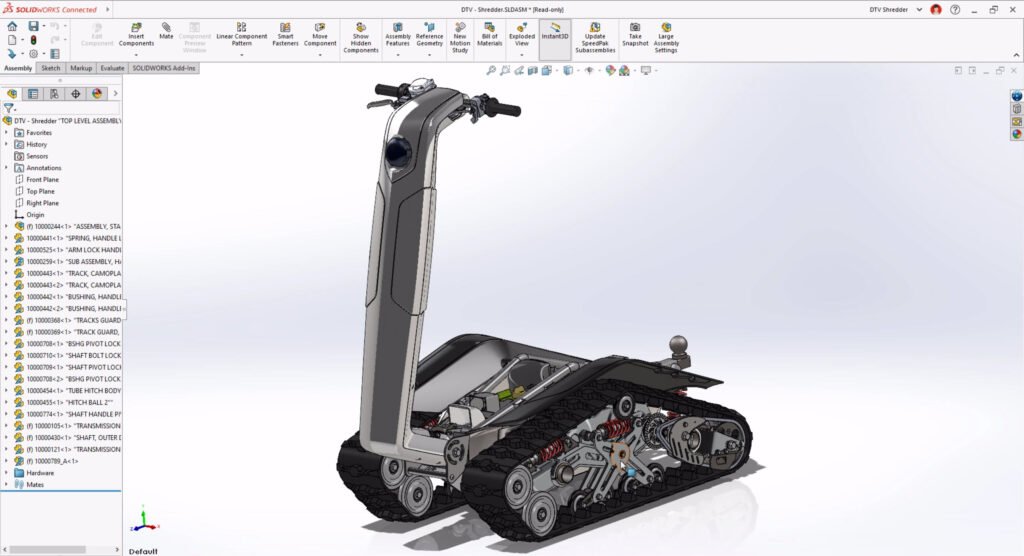

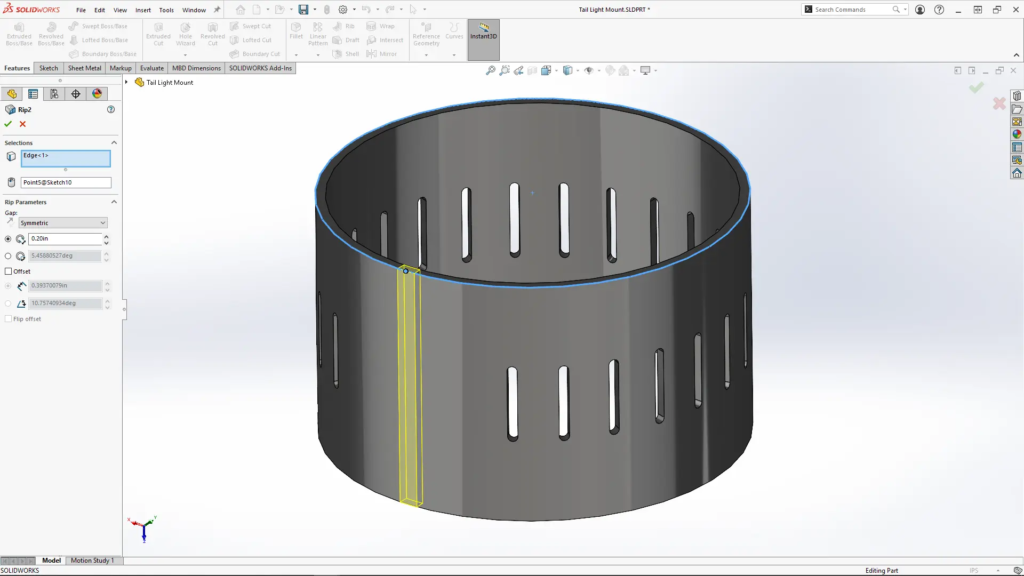

What Are 3D Models in Metal Fabrication and Manufacturing?

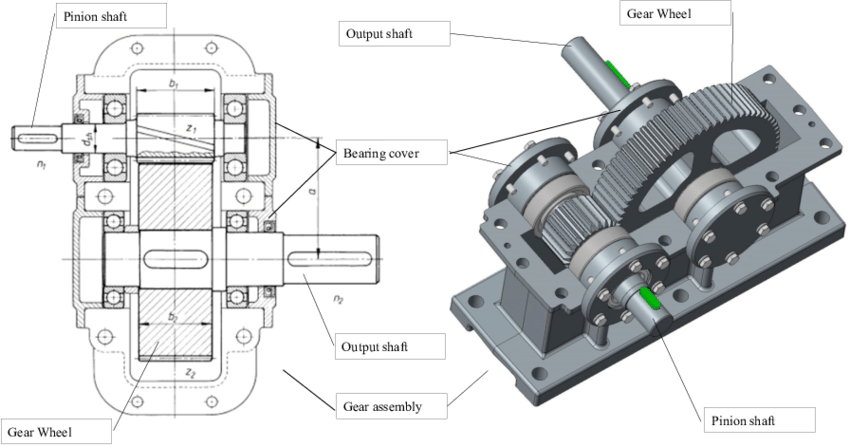

3D models are three-dimensional representations of metal components that incorporate depth, in addition to height and width. Unlike 2D CAD drawings, which focus on flat projections, 3D models offer a life-like view of a part, showing its volume, contours, and even material properties.

Key applications of 3D models in metal fabrication and manufacturing include:

- Prototyping and Simulation: Allowing manufacturers to test designs for fit, functionality, and stress points before production.

- Complex Assemblies: Visualizing how multiple components fit together, ensuring seamless integration.

- Customization and Design Iteration: Enabling rapid modifications to adapt to unique client requirements or evolving specifications.

- Advanced Manufacturing Processes: Technologies like additive manufacturing (3D printing) and multi-axis CNC machining rely heavily on 3D models to achieve precision.

By using 3D models, manufacturers can eliminate potential errors, optimize material usage, and visualize the final product more effectively, which is particularly valuable for intricate or high-value projects.

Why Discuss 2D CAD Drawings and 3D Models in Metal Fabrication?

Both 2D CAD drawings and 3D models are integral to the metal fabrication process. While 2D drawings excel in providing clear, straightforward production instructions, 3D models offer unmatched versatility and detail for modern manufacturing needs. Understanding their respective roles helps fabricators and engineers choose the right tool for the task, balancing efficiency, cost, and precision.

2D vs. 3D CAD: Understanding the Key Differences

The fundamental difference between 2D and 3D CAD lies in dimensionality.

- 2D CAD: Represents a two-dimensional design, displaying only height and length on a flat plane without depth.

- 3D CAD: Represents a three-dimensional design, displaying width, height, and depth, creating a more immersive and realistic simulation of the project.

Both formats have their unique strengths:

- 3D CAD: Offers advanced features for real-life simulation, enabling designers to make edits more efficiently and reduce design time.

- 2D CAD: Provides a simpler, more accessible option that is ideal for pre-construction sketches, quick designs, and site management tasks.

While 3D CAD excels in creating detailed models and visualizations, it presents certain challenges that make 2D CAD a preferred option in many scenarios, particularly for site foremen.

The Benefits of 2D CAD Drawings

Although 3D CAD technology has advanced significantly, 2D CAD continues to be an invaluable tool for construction teams due to the following benefits:

1. Easy to Understand and Interpret

2D CAD drawings are straightforward and widely understood by designers, engineers, and site workers.

- Reduced Learning Curve: Unlike 3D CAD, which requires specialized training, 2D CAD eliminates steep learning curves.

- Improved Collaboration: Since most team members are familiar with 2D designs, it simplifies communication and boosts productivity.

This accessibility makes it easier for teams to interpret designs and ensures smooth project delivery.

2. More Efficient for Specific Tasks

2D CAD excels in tasks that require simplicity and speed.

- Project Contracts and Conceptual Designs: 2D CAD drawings are often used for contracts and pre-construction sketches, providing a quick overview of a project’s scale and size.

- Drafting and Sketching: They are ideal for creating drafts and sketches that offer clarity without the need for complex layers.

For site foremen, 2D CAD is the go-to tool for on-site referencing and immediate decision-making.

3. Easily Accessible and Editable

2D designs are lightweight and can be accessed or edited with minimal resources.

- Minimal Storage Requirements: Unlike 3D models, which require significant memory and advanced hardware, 2D designs can be edited on standard computers.

- Quick Updates: Making changes to 2D drawings is faster and more straightforward than updating 3D models.

This flexibility is essential for construction projects where changes are frequent and time-sensitive.

4. Cost-Effective

2D CAD solutions are more economical than 3D CAD for several reasons:

- Lower Production Costs: Creating 2D designs requires less time, software, and hardware investment.

- No Need for Specialized Experts: Most construction professionals are already familiar with 2D CAD, eliminating the need to hire specialized 3D modelers.

These cost savings are particularly beneficial for smaller construction firms operating on tight budgets.

5. Portable and Easy to Share

On-site practicality is a significant advantage of 2D CAD drawings.

- Printed Blueprints: Foremen can easily carry printed 2D drawings, which can be hung on walls or shared with teams on the go.

- Remote Access: 2D CAD drawings can be shared via email or accessed on-site without requiring high-end devices.

This portability ensures uninterrupted workflows, even in remote or technologically limited areas.

Challenges with 3D CAD Models

While 3D CAD technology offers incredible design capabilities, it comes with challenges that hinder its universal adoption:

1. High Costs

- Expensive Hardware and Software: Running 3D models requires costly computers, software, and even 3D printers.

- Additional Maintenance Costs: Maintaining these tools and training staff to use them can further inflate expenses.

Small to medium-sized construction firms often find these costs prohibitive.

2. Requires Specific Skills

3D modeling demands expertise in advanced techniques such as rendering, animation, and rigging.

- Labor Shortages: The construction industry already faces a significant labor shortage, making it difficult to find skilled 3D modelers.

- Long Training Periods: Training existing staff in 3D modeling can take time, delaying project schedules.

This skills gap is a significant barrier to the widespread adoption of 3D CAD.

3. Time-Consuming

The complexity of creating and editing 3D models makes them less suitable for projects with tight deadlines.

- Slower Turnaround: Generating a conceptual 3D design can take hours or even days, making it impractical for quick client presentations.

- Inefficient for On-Site Use: 3D models often require digital devices for viewing, which can be cumbersome for site foremen.

For time-sensitive tasks, 2D CAD provides a faster and more efficient alternative.

Striking a Balance Between 2D and 3D CAD

Rather than viewing 2D and 3D CAD as competitors, it’s important to recognize how they complement each other in modern construction workflows:

- 2D for Execution: Ideal for pre-construction drawings, contracts, and on-site tasks that require simplicity and speed.

- 3D for Design: Perfect for complex designs, client presentations, and coordination among stakeholders.

By leveraging the strengths of both tools, construction teams can achieve a balance between clarity, innovation, and efficiency.

Conclusion: Why 2D CAD Drawings Endure

The simplicity, accessibility, and cost-effectiveness of 2D CAD drawings make them indispensable for site foremen and construction teams. While 3D CAD excels in complex modeling and visualization, 2D CAD remains the backbone of on-site operations, ensuring projects run smoothly and efficiently.

At Lux Metal Group, we specialize in delivering high-quality metal solutions tailored to your construction needs. Whether you’re working with 2D or 3D designs, our team ensures precision and excellence in every project.

Visit Lux Metal Group today to learn how we can support your next construction project.

For further insights, explore: