What is Rebar?

Rebar is a steel bar used as a tension device in reinforced concrete and masonry structures. It helps hold the concrete in compression, increasing its strength and preventing cracking or failure under load. Its use is essential in structures like buildings, bridges, roads, and dams where stability and durability are non-negotiable.

Why Steel is Used for Rebar

Steel is the preferred material for rebar because its thermal expansion coefficient closely matches that of concrete. This means that both materials expand and contract at similar rates when exposed to temperature changes, reducing the risk of cracking. Additionally, steel offers the ideal combination of tensile strength, ductility, and bonding ability when embedded in concrete.

Types of Rebars

1. Mild Steel Bar

- Surface: Smooth and round.

- Sizes: Available in diameters from 6 mm to 50 mm.

- Applications: Used in specific areas like expansion joints, contraction joints, and column spirals.

- Limitations: Not ideal for major structural work due to lower bonding strength with concrete and potential slippage.

2. Deformed Steel Bar

- Surface: Features ribs or lugs to improve bonding with concrete.

- Advantages: Reduces slippage and enhances tensile strength.

- Sizes: Produced in diameters from 6 mm to 50 mm.

- Applications: Ideal for slabs, columns, foundations, and structures in seismic zones.

3. TMT Bars (Thermo Mechanically Treated Bars)

- Strength: High tensile strength and ductility.

- Properties: Excellent bending, welding ability, and corrosion resistance.

- Applications: Used extensively in RCC structures, especially in earthquake-prone zones.

4. High Strength Deformed Bars (HSDB)

- Features: Cold twisted bars with exceptional tensile strength and corrosion resistance.

- Applications: High-rise buildings, bridges, industrial facilities, and structures in high-stress or corrosive environments.

Rebar Bending and Technology

Rebar bending is a crucial process in construction. It involves shaping steel bars to precise specifications as part of a bar bending schedule, which ensures structural compliance and safety. Bending can be done manually or using hydraulic and industrial machines, depending on the project scale.

Bending Schedule

The bending schedule is a documented plan that specifies how bars should be bent, cut, and placed. This ensures:

- Correct material usage.

- Compliance with building codes.

- Structural integrity and safety.

Difference Between Rebar and Steel Bar

| Aspect | Reinforcing Bar (Rebar) | Bar (Steel Bar) |

|---|---|---|

| Surface Characteristics | Ribs or deformations | Smooth surface |

| Primary Role | Enhances tensile strength of concrete | General structural support |

| Common Materials | Carbon steel, stainless steel | Carbon steel |

| Applications | RCC buildings, bridges, roads | Hangers, supports, grillage beams |

Applications of Rebar

Rebar is essential in many concrete-based structures:

- Buildings: Reinforces beams, slabs, and columns.

- Bridges: Strengthens decks and support columns.

- Roads & Infrastructure: Adds stability to pavements, retaining walls, and tunnels.

- Industrial Projects: Used in factories, warehouses, and plants.

- Seismic Zones: Provides structural resilience during earthquakes.

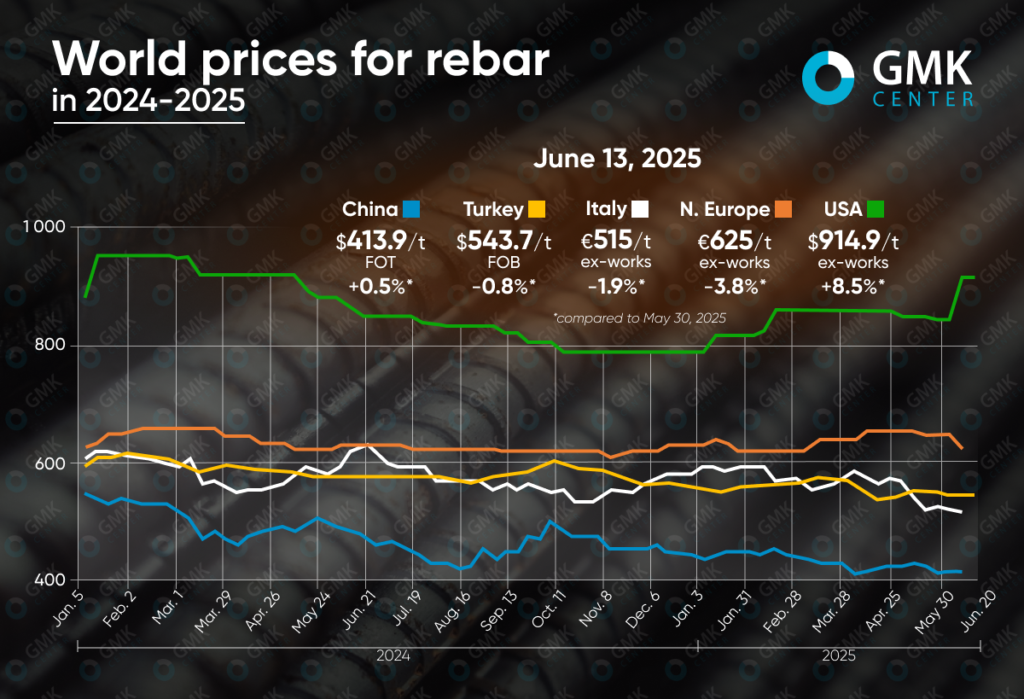

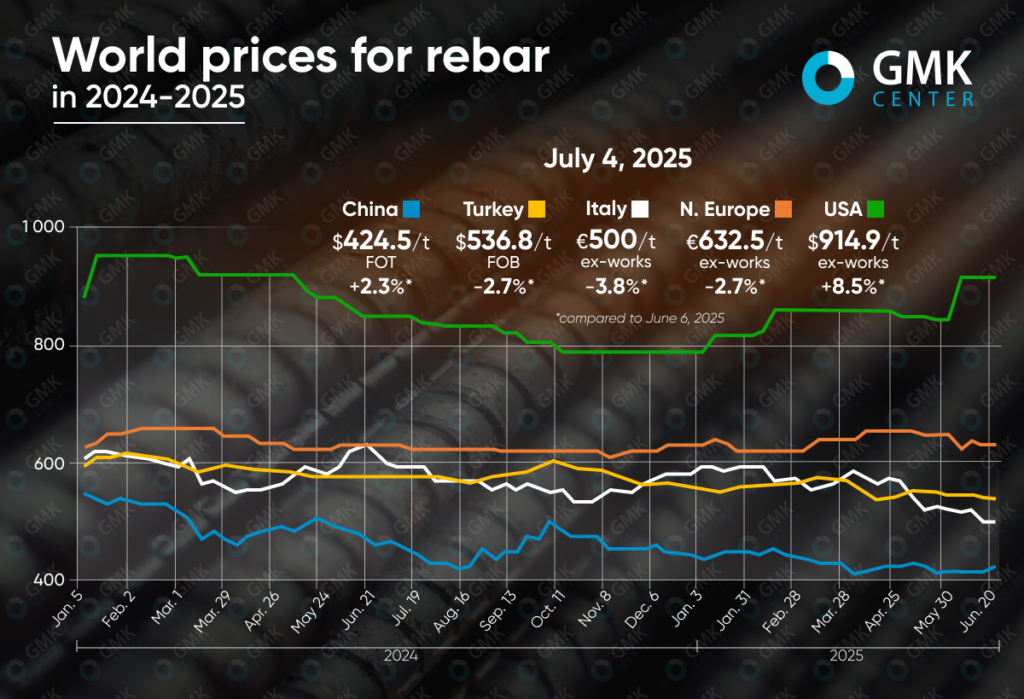

Global Rebar Market Outlook – June 2025: Diverging Trends Across Regions

The global rebar market in early June 2025 displayed a mix of stability and volatility across major regions. Influenced by fluctuating scrap prices, geopolitical decisions, and subdued construction activity, regional disparities have grown sharper, creating a complex landscape for buyers and producers alike.

🔻 Turkey: Market Under Pressure from All Sides

Rebar prices in Turkey fell by 0.8% to $543.75/t FOB in the first half of June. Weak demand across both domestic and export markets, combined with high interest rates and the Eid al-Adha holiday, kept purchasing activity subdued.

While minor gains in demand were observed from Syria and Northern Cyprus, the broader outlook remains pessimistic. Mills responded by turning to cheaper imported billets, particularly from China and Asia, to cut costs amid falling scrap prices.

Forecasts for late June suggest a flat or downward trend unless the Turkish Central Bank lowers interest rates—expected on June 19. Even then, any positive impact is expected to be short-lived.

🔻 European Union: Demand Drop Sparks Price Slide

The EU rebar market continued its downward spiral, particularly in Northern Europe, where prices fell 3.8% to €625/t ex-works. Italy also reported a 1.9% drop to €515/t. German base prices slipped below €400/t amid rising caution among buyers.

This decline is fueled by weak private sector construction demand, ongoing corrections in scrap prices, and stiff competition from imports—particularly from Turkey, Algeria, and Spain.

Although infrastructure demand is showing signs of recovery, the market remains vulnerable. Any rebound depends on scrap price stabilization and accelerated government-backed projects.

🔺 United States: Tariffs Drive Sudden Surge

In sharp contrast, the U.S. rebar market saw an 8.5% price increase, reaching $914.9/t, following President Trump’s announcement to double steel import tariffs to 50% under Section 232.

Major U.S. producers, including Steel Dynamics, CMC, Gerdau, and Nucor, quickly raised prices by $60–100/t in response. Spot prices jumped to $810–850/t, fueled by constrained import availability and anti-dumping actions.

However, despite these bullish moves, underlying demand from commercial and residential construction remains soft, with infrastructure projects being the only consistent demand pillar.

🔸 China: Stability Amid Seasonal Lull

Chinese rebar prices rose slightly by 0.5% to $413.9/t FOT. Still, weak demand persists due to seasonal weather disruptions—heavy rain in the south and extreme heat in the north.

Most buyers are limiting purchases to essentials, while speculative activity stays muted. On the supply side, producers are cautious but not aggressive in production cuts, thanks to improved blast furnace margins.

Top mills like Shagang and Yonggang maintained price levels and offered buyer subsidies, reflecting market sensitivity to demand. Any strong recovery will depend on government stimulus or post-summer demand rebound.

🌍 June 2025 Global Rebar Market Overview: Seasonal Pressures and Policy Shocks Shape Regional Trends

The global rebar market in June 2025 is experiencing notable shifts shaped by seasonal construction slowdowns, weak demand, and policy-driven volatility. While key regions like Turkey, the EU, and China are witnessing stagnation or decline, the U.S. market is defying the trend, posting sharp gains fueled by tariffs and supply-side adjustments.

🇹🇷 Turkey: Demand Wanes Amid Economic Strain

Turkey’s rebar prices dipped 0.8% to $543.75/t FOB in early June. The drop is largely driven by sluggish domestic and export demand, tight financial conditions, and the Eid al-Adha holiday period.

- Export activity remained muted as European buyers hesitated due to uncertain July quotas. Only slight upticks were noted in demand from Syria and Northern Cyprus.

- Domestic activity was hampered by high interest rates and macroeconomic pressure.

- Turkish mills leaned towards importing billets from Asia, where prices were lower than domestic scrap or billet rates.

📉 Outlook: Price trends are expected to stay weak, with a possible short-term boost if the Turkish Central Bank lowers interest rates on June 19.

🇪🇺 European Union: Downtrend Continues Despite Hints of Recovery

Rebar prices in Europe continued their downward trajectory, reflecting soft demand and increased import competition.

- Northern Europe saw the steepest decline, with prices falling 3.8% to €625/t ex-works—the lowest since March.

- Italy’s prices dropped 1.9% to €515/t, despite gradual improvement in infrastructure sector demand.

- In Germany, base prices fell below €400/t, with total costs including surcharges settling at €645–655/t.

🔻 Buyers are delaying purchases, expecting further drops. Meanwhile, imports from Algeria, Turkey, and Spain are intensifying pressure on EU producers.

📉 Outlook: Prices may rebound slightly if scrap prices stabilize, but the overall trend remains bearish.

🇺🇸 United States: Tariff Hike Triggers Price Surge

The U.S. rebar market jumped 8.5% to $914.9/t in early June, bucking global trends.

- A key driver was President Trump’s decision to double steel import tariffs to 50% under Section 232.

- Major producers like Nucor, Gerdau, CMC, and Steel Dynamics swiftly raised prices by $60–100/t.

- Spot prices climbed to $810–850/t, reflecting limited availability of imports and active anti-dumping probes.

🚧 Despite construction activity being somewhat sluggish, infrastructure projects continue to provide a demand backbone.

📈 Outlook: The market may stabilize in current ranges, with tariff impacts and scrap demand remaining key influencers.

🇨🇳 China: Cautious Stability Amid Seasonal Disruptions

In China, rebar prices edged up 0.5% to $413.9/t FOT, reflecting subdued demand and weather-related slowdowns.

- Activity was limited by rain in the south and heat in the north, which constrained site operations.

- Buyers remained cautious, only purchasing to fulfill immediate needs.

- On the supply side, steelmakers held back from aggressive production cuts, thanks to favorable blast furnace margins.

- Leading mills like Shagang and Yonggang kept prices steady while offering subsidies to support the market.

📉 Outlook: In the absence of significant government stimulus or demand recovery, the market is expected to hover around current levels.

📊 Summary: Diverging Paths Ahead

| Region | Price Trend | Key Drivers |

|---|---|---|

| Turkey | 🔻 Decline | Weak export/domestic demand, high interest rates |

| EU | 🔻 Decline | Low construction activity, import pressure |

| USA | 🔺 Surge | Tariffs, mill pricing actions |

| China | ➖ Slight Rise | Seasonal slowdown, stable production |

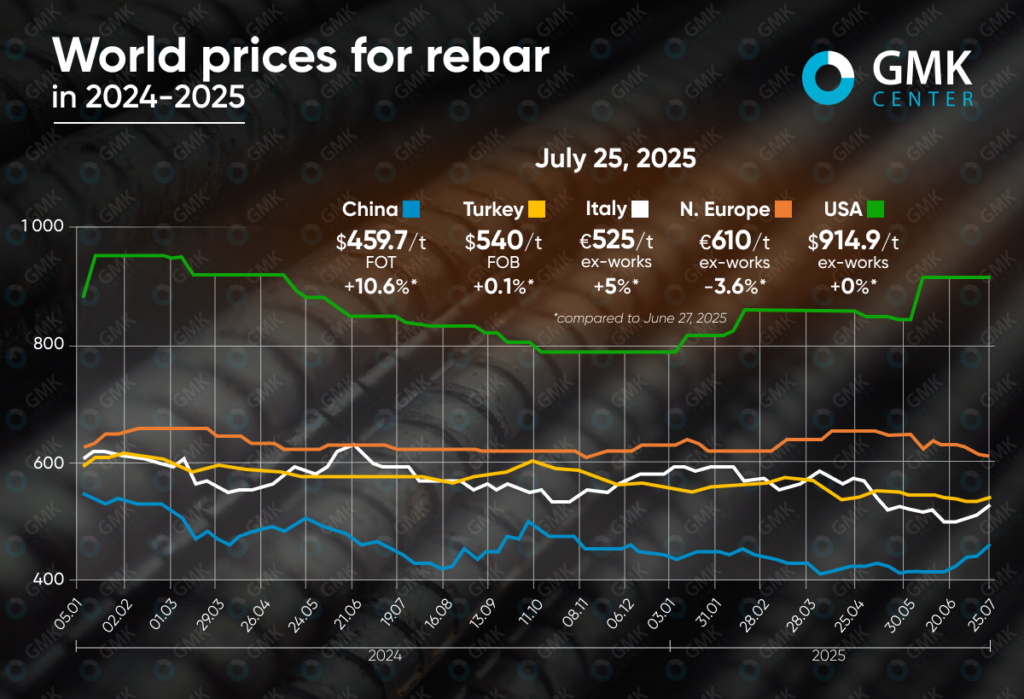

🌍 July 2025 Global Rebar Market Trends: China Surges, Europe and Turkey Struggle, U.S. Holds Steady

The global rebar market in July 2025 displayed mixed dynamics, influenced by regional demand shifts, macroeconomic factors, and seasonal slowdowns. While China recorded a sharp price rebound on the back of policy optimism and rising raw material costs, the European and Turkish markets continued to face headwinds. Meanwhile, the U.S. market remained relatively stable after June’s price hikes.

🇨🇳 China Leads the Surge with Price Rally

China experienced a notable upswing in rebar prices, climbing 10.6% to $459.7/t FOT Warehouse by the end of July. The boost was fueled by:

- Speculation over production restrictions

- Anticipated macroeconomic stimulus measures

- Bullish futures market sentiment

- Support from large-scale infrastructure initiatives such as the hydropower project on the Yarlung Tsangpo River

Despite being a low-demand season due to summer rains and heat, the surge in spot and futures prices drove optimism among steel producers. This was further reinforced by reduced inventories and cost-push pressures from rising raw materials.

🇹🇷 Turkey Faces Downward Pressure

In contrast, Turkey’s rebar market remained fragile, with only a 0.1% price increase to $540/t FOB from June 27 to July 25. Mid-month prices dipped to $520/t due to:

- Subdued domestic and export demand

- High EU import duties (12–13%) after quota limits were exceeded

- Geopolitical instability and summer holiday season

While producers like Kardemir attempted price hikes to $545–550/t citing China’s rebound, demand remained weak. Export volumes to regions like Palestine, Ethiopia, and the Balkans were minimal. Despite an interest rate cut by Turkey’s Central Bank, financing constraints continued to suppress domestic consumption.

🇪🇺 Europe: Divided Market Sentiment

Europe’s rebar prices mirrored a split trend:

- Northern Europe: Prices declined 3.6% to €610/t ex-works amid:

- Weak construction activity

- Fierce competition among producers

- Seasonal slowdown

- Italy: Rebounded 5% to €525/t ex-works due to:

- Low inventory levels

- Rising production costs

- Restocking before August shutdowns

Germany and Austria saw continued declines, while France remained stable but lacked real demand. Southern regions felt pricing pressure from cheaper imports, especially from Spain and Italy.

🇺🇸 United States Holds Ground

In the U.S., rebar prices plateaued at $915/t after an 8.5% rise in June. Producers’ efforts to raise prices further were stymied by:

- High interest rates

- Ongoing construction slowdown

- Geopolitical and trade uncertainty

Despite anti-dumping investigations into imports from Algeria, Vietnam, Egypt, and Bulgaria, domestic prices were propped up by:

- Tight supply expectations

- Tariff impacts

- Nucor’s 10% price increase announcement

However, further growth was restrained by weak real demand signals and cautious investor sentiment.

🔍 Summary: July 2025 – A Market of Contrasts

| Region | July Trend | Key Drivers |

|---|---|---|

| China | 🔼 Sharp Increase | Policy optimism, production curbs, infrastructure demand |

| Turkey | 🔽 Vulnerable | Weak demand, EU duties, oversupply |

| Europe | 🔄 Mixed | Low construction activity vs. inventory-driven recovery |

| USA | ➖ Stable | Previous hikes, limited demand, cautious optimism |

What Is Rebar Used For?

Rebar is primarily used to carry tensile loads in concrete and masonry structures. Without rebar, concrete would crack and eventually fail under stress, especially in heavy load-bearing areas like roads, bridges, and multi-story buildings.

Where Is Rebar Used?

Rebar is commonly used in:

- Buildings (foundations, beams, columns, slabs)

- Roads and highways

- Bridges and overpasses

- Dams and water tanks

- Retaining walls

When Is Rebar Needed in Concrete?

Rebar is essential in concrete structures that bear heavy loads—such as foundations, footings, columns, and roadways. Smaller projects like garden paths or shed floors might not require rebar, but even in these cases, adding steel reinforcement can boost durability and prevent cracking.

What Are Rebar Sizes?

In the U.S., rebar sizes range from #3 to #18:

- #3 = 3/8 inch diameter

- #4 = 1/2 inch diameter

- #5 = 5/8 inch diameter

…and so on.

The number corresponds to the bar’s diameter in eighths of an inch (e.g., #8 = 8/8 = 1 inch).

What Are Rebar Chairs?

Rebar chairs are supports used to hold rebar in position before concrete is poured. They ensure that the steel is elevated to the proper height, allowing concrete to fully encapsulate it and provide the correct coverage.

What Are Rebar Couplers?

Rebar couplers connect two pieces of rebar end-to-end, eliminating the need for overlapping (lap joints). They simplify design, reduce congestion in steel layouts, and improve structural integrity.

What Is Rebar Made Of?

Rebar is typically made from carbon steel, though stainless steel, glass-fiber-reinforced polymer (GFRP), and epoxy-coated versions are also available depending on corrosion resistance and project requirements.

What Is Rebar Fabrication?

Rebar fabrication involves:

- Cutting

- Bending

- Threading or finishing ends

This process is guided by engineered rebar schedules and drawings. Fabrication ensures each piece fits the structural design exactly.

Why Does Rebar Have Ridges?

The ridges on rebar (called deformations) are designed to enhance its bond with concrete. This prevents slippage and increases structural strength during tension.

What Is Rebar Threading?

Threading involves cutting spiral grooves into the end of a rebar using a machine. This allows it to be connected to couplers or anchoring systems for structural reinforcement.

Can Rebar Be Bent?

Yes. Rebar is bent to fit design specifications—typically using machines in fabrication shops. Bending must be done carefully, as improper techniques can weaken the steel and lead to structural failure.

Can Rebar Be Cut?

Absolutely. Rebar can be cut using tools like:

- Metal saws

- Torches

- Band saws

- Shear presses (in professional shops)

Proper cutting ensures clean joints and accurate lengths per design.

How Does Rebar Work?

Once embedded in concrete, rebar resists tensile forces and controls cracking. The bond between the concrete and steel allows both materials to act as one—concrete handles compression, and steel handles tension.

How Much Rebar Do You Need?The quantity of rebar depends on:

- The size of the project

- Load requirements

- Bar size and spacing

Engineers typically calculate this using structural drawings and reinforcement schedules.

How Do You Connect Rebar?

Rebar can be connected using:

- Couplers

- Lap splicing (overlapping two bars)

- Welding (in specific cases)

Each method has its own structural and code requirements.

What Is Wire Mesh Used For?

Wire mesh reinforces concrete slabs, such as driveways and floors. It provides tensile strength and helps distribute loads evenly across the slab surface.

What Are Dowel Bars Used For?

Dowel bars connect different concrete components, like foundations and slabs. They provide structural continuity and help transfer loads across joints.

What Is Epoxy Coating For?

Epoxy coatings protect rebar from corrosion, especially in environments exposed to water, salt, or chemicals. This extends the lifespan of the steel and the concrete structure.

How Do You Tie Rebar Cages?

Rebar cages are tied using wire and pliers to hold the bars in position. A common method is the double snap tie, which secures the bars tightly to prevent movement during concrete pouring.

Conclusion: The Backbone of Concrete

Rebar is a vital part of any concrete structure—providing the necessary strength, flexibility, and durability for both small-scale and massive infrastructure projects. From simple footpaths to towering skyscrapers, rebar is what allows concrete to do the heavy lifting safely and efficiently.

Whether you’re a builder, contractor, engineer, or architect, understanding the fundamentals of rebar ensures that your concrete structures can stand the test of time.

🔧 Reinforced With Precision: Lux Metal’s Rebar Fabrication & Supply Services

At Lux Metal, we specialize in precision rebar fabrication, cutting, bending, threading, and epoxy coating to meet the most demanding construction standards. Whether it’s for high-load foundations, infrastructure projects, or custom steel works, we ensure each steel element is fabricated to your exact specs — with CNC accuracy, durability, and certified quality.

Looking for consistent supply of rebars, couplers, or custom-fabricated rebar cages? Contact Lux Metal to elevate your structural strength.

At LUX METAL, we specialize in customized steel and stainless steel fabrication, offering precision solutions for contractors, builders, and fabricators. Our services include:

- Rebar processing and cutting

- CNC bending and shaping

- On-demand bulk orders for construction-grade steel

- End-to-end logistics and delivery support

Reach out to us at www.luxmetalgroup.com to learn how we can support your project needs.

📚 References

To learn more about rebar industry trends, fabrication processes, and global market conditions, explore the following authoritative resources:

- GMK Center – Global rebar prices have been under pressure since early June

- GMK Center – Global rebar prices are under pressure from seasonal factors

- GMK Center – Rebar prices fluctuate in July under pressure from demand and local factors

- AngleRoller – Reinforcing bar vs bar: What is rebar bending?

- IntereBar – Rebar Facts