1. Understanding ISO Standards in Metal Manufacturing

ISO standards serve as a global benchmark for quality and consistency. Key standards relevant to metal manufacturing include:

- ISO 9001: Focuses on QMS to enhance customer satisfaction through effective processes.

- ISO 14001: Addresses environmental management, ensuring sustainable operations.

- ISO 45001: Ensures occupational health and safety.

Why ISO Matters in Metal Manufacturing

- Global Credibility: Demonstrates adherence to international best practices.

- Operational Efficiency: Standardized processes reduce waste and errors.

- Customer Confidence: Guarantees consistent quality in products and services.

2. Establishing a Quality Management System (QMS)

A QMS forms the backbone of ISO compliance, detailing every aspect of the production process.

Key Components of a QMS

- Process Documentation: Clear procedures for every operation, from procurement to final delivery.

- Responsibilities and Roles: Defined accountability for all team members.

- Quality Policies: A commitment to meeting customer and regulatory requirements.

Steps to Build an ISO-Compliant QMS

- Map out processes and workflows.

- Identify key performance indicators (KPIs).

- Develop control plans for critical operations.

Reference: What is a Quality Management System (QMS)?

3. Setting Quality Objectives and Goals

Quality objectives drive improvements and align operations with ISO principles.

Examples of Quality Objectives in Metal Manufacturing

- Reduce defect rates by 10% in a year.

- Improve on-time delivery performance to 95%.

- Achieve 100% compliance with material specifications.

SMART Framework

Ensure objectives are Specific, Measurable, Achievable, Relevant, and Time-bound.

4. Supplier Quality Management

Suppliers play a vital role in the quality of finished products.

ISO-Compliant Supplier Management Practices

- Selection Criteria: Assess suppliers based on material quality, certifications, and delivery performance.

- Regular Audits: Verify supplier processes and raw material quality.

- Performance Reviews: Monitor and communicate key metrics like defect rates and delivery timelines.

Case Study

A sheet metal manufacturer reduced material defects by 15% by implementing a supplier evaluation program.

5. Raw Material Inspection and Testing

Raw materials form the foundation of quality. Rigorous inspection ensures compliance with specifications.

Common Tests in Metal Manufacturing

- Chemical Analysis: Verifies composition using spectrometers.

- Mechanical Testing: Assesses tensile strength, hardness, and impact resistance.

- Non-Destructive Testing (NDT): Detects internal flaws without damaging materials.

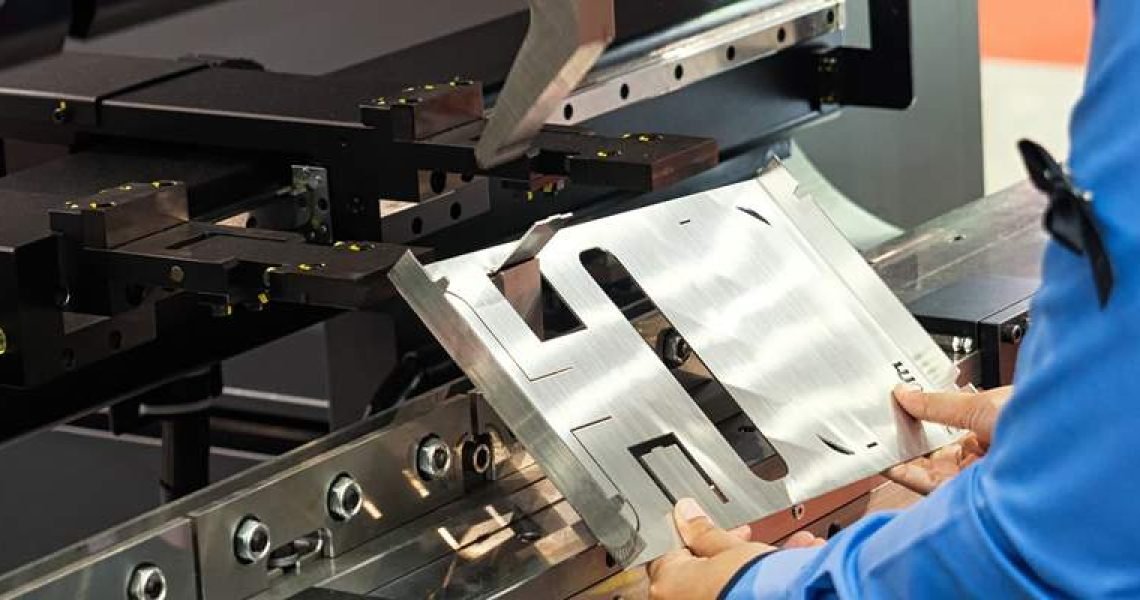

6. Production Process Control

Maintaining quality during production is critical to ISO compliance.

Key Process Controls

- Work Instructions: Step-by-step guides for operators.

- Real-Time Monitoring: Use of sensors and software to track parameters like temperature and pressure.

- Statistical Process Control (SPC): Identifies trends to prevent defects.

Practical Example

A die-casting company reduced scrap rates by 20% using SPC to control mold temperature.

7. In-Process and Final Inspections

Regular inspections ensure that products meet specifications at every stage.

In-Process Inspections

- Visual checks for surface defects.

- Dimensional measurements using calipers or coordinate measuring machines (CMM).

Final Inspections

- Comprehensive testing to verify compliance with customer specifications.

- Documentation of results for traceability.

8. Employee Training and Competence

Skilled employees are essential for maintaining quality.

Training Programs for ISO Compliance

- Quality assurance principles.

- Operation of inspection equipment.

- Safety and environmental protocols.

Benefits of Training

- Reduced errors and rework.

- Enhanced employee engagement.

9. Continuous Improvement Culture

ISO standards emphasize continual improvement.

Key Strategies

- Kaizen: Encourage small, incremental changes.

- Root Cause Analysis: Use tools like fishbone diagrams to identify and address issues.

- Customer Feedback: Gather insights to refine processes.

10. Internal Audits and ISO Certification

Audits ensure adherence to ISO standards and identify areas for improvement.

Internal Audit Process

- Develop a checklist based on ISO requirements.

- Conduct interviews and review documents.

- Report findings and corrective actions.

Steps to Achieve Certification

- Engage a certification body.

- Prepare for external audits.

- Address any non-conformities identified.

Benefits of ISO-Compliant Quality Processes in Metal Manufacturing

Operational Advantages

- Streamlined workflows.

- Reduced waste and costs.

Market Advantages

- Enhanced reputation and customer trust.

- Access to international markets.

Sustainability and Safety

- Improved environmental performance.

- Safer working conditions for employees.

Conclusion

Mastering the quality process in metal manufacturing with ISO standards is a pathway to operational excellence, customer satisfaction, and sustainable growth. By adhering to these rigorous guidelines, manufacturers can achieve a competitive edge in an increasingly demanding market.

Ready to implement ISO standards? Start by evaluating your current processes, engaging experts, and committing to continuous improvement. The journey may be challenging, but the rewards are immeasurable.

Partner with Us Today

At LUX METAL, we take pride in being a trusted partner for metal fabrication in Malaysia. With our comprehensive range of machinery, skilled team, and dedication to quality, we are ready to tackle your next project with precision and professionalism.

Whether you’re looking for a one-time production run or a long-term partnership, we’re here to help. Contact us today to learn more about our services and how we can bring your ideas to life.