🇺🇸 How the United States Forged a Path to Green Steel Leadership — Lessons the World Can’t Ignore

Long before climate regulations and carbon neutrality goals took center stage in global policy, the U.S. steel industry made a bold move. American steel producers began transforming their manufacturing methods decades ago—well ahead of the EU and other global regions—by shifting to cleaner, more flexible electric arc furnace (EAF) technology. This early adoption positioned the United States as a global frontrunner in sustainable steelmaking.

🔁 Early Industry Restructuring: The Shift to Electric Arc Furnaces

In the mid-1970s, the American steel sector was structured much like its European counterpart—built around blast furnace-basic oxygen furnace (BF-BOF) plants. With over 45 BF-BOF operations across the country and mega-facilities like Gary Works in Indiana producing millions of tons annually, the industry was deeply tied to high-emission steelmaking.

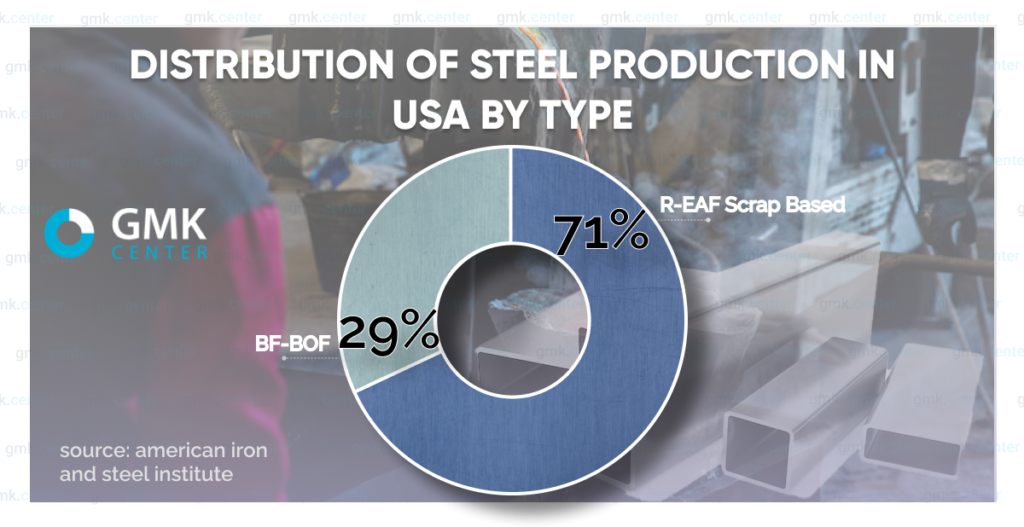

But everything changed in the early 1980s. The U.S. began adopting recycled electric arc furnace (R-EAF) mini-mills. These compact, scrap-based plants offered speed, adaptability, and cost-efficiency. Producers could quickly switch production from one steel grade to another and respond faster to market demands.

By 1992, the U.S. operated 65 EAF mills with a capacity of 25 million tons. Fast forward to 2001, and over 90 mills were running—delivering nearly 92 million tons annually. This massive transition required over $23 billion in capital investment, a bold move that has paid off many times over.

♻️ Scrap Power: Building a Self-Reliant and Sustainable Supply Chain

One of the most strategic aspects of the U.S. transition to EAF production is raw material independence. Instead of relying on imported iron ore, the U.S. focused on domestic steel scrap. By 2024, the country was collecting over 73.3 million tonnes of scrap annually.

Simultaneously, direct reduced iron (DRI) production surged. From just 0.51 million tons in 1998, it soared to 5.24 million tons by 2022. These parallel developments ensured a steady supply of EAF-compatible feedstock—fueling sustainability at scale.

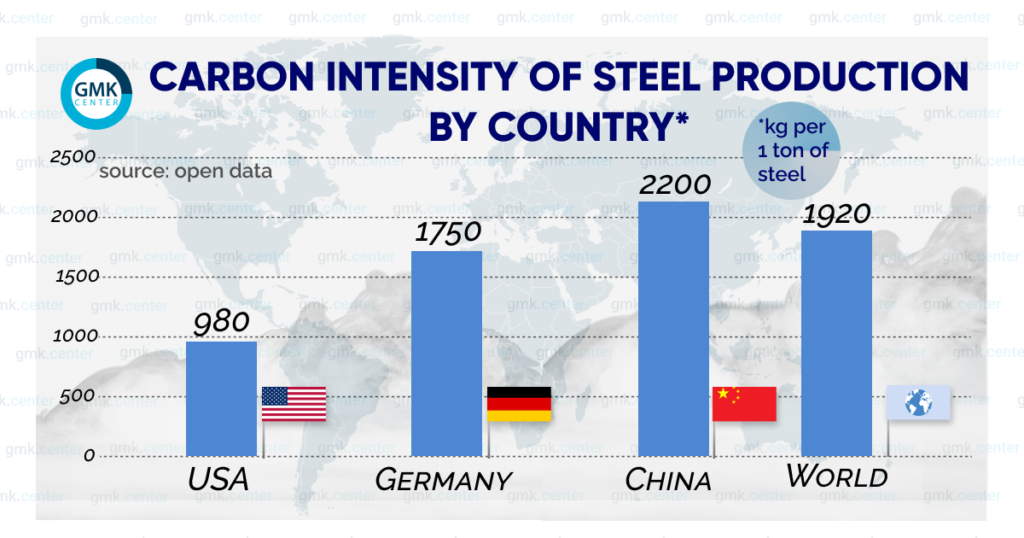

According to Brandon Farris, VP of the Steel Manufacturers Association, U.S. steelmakers are now 75–320% more carbon-efficient than their global peers.

Most American mills are now R-EAF-based, producing just 0.39 to 0.8 tons of CO₂ per ton of steel—well below global averages and in full alignment with environmental benchmarks. This is a stark contrast to Europe, where “green premiums” are added to steel prices. In the U.S., eco-friendly steel costs the same as conventional—removing a critical market barrier.

💡 America’s Decarbonization Model: Driven by Investment and Innovation

The move toward net-zero emissions in American steel production gained momentum under the Biden administration. All major steel companies aligned with the policy direction and invested heavily in innovation, far beyond regulatory compliance.

Take Nucor for example. The steel giant invested $15M and $35M in NuScale and Helion—two ventures developing small-scale nuclear and fusion reactors to power steel mills in Alabama and Arkansas by 2030.

And that’s just the beginning.

Major Green Steel Projects in the U.S.:

- Nucor & ExxonMobil: Carbon capture project in Louisiana to store up to 800,000 tons of CO₂ annually by 2026.

- Cleveland-Cliffs: Developing a 2.5 million-ton H₂ DRI plant in Ohio with twin 120MW EAFs, replacing legacy blast furnaces.

- U.S. Steel & Equinor: Carbon capture agreements signed in 2021 for facilities across Ohio, Pennsylvania, and West Virginia.

- Gary Works, Indiana: A plan to capture and mineralize 50,000 tons of CO₂ per year using CarbonFree’s SkyCycle™ tech.

While Europe focused on “green steel factories of the future” with hydrogen-based DRI-EAF combinations, U.S. producers took a more practical route—combining carbon capture, DRI, and scrap-based EAFs. This strategy is cheaper, scalable, and already delivering results.

💰 Strategic Acquisitions & Forward Policy Planning

The recent acquisition of U.S. Steel by Japan’s Nippon Steel is a strong signal of continued green transformation. A $7 billion investment will support the company’s shift from BF-BOF to scrap-based R-EAF facilities.

This transaction was approved by the U.S. government with one critical condition: it must accelerate the decarbonization of U.S. Steel’s operations. This alignment between policy and industry showcases how America’s green steel agenda is being enforced not just by regulations—but also by investment conditions.

🛡️ Smart Trade Policy: Protecting the Green Transition

The 50% tariff imposed in 2018 under President Trump shielded the American market from low-cost, high-emission steel imports. This market protection enabled local producers to invest in greener technologies without being undercut.

Now, the U.S. is considering a Carbon Border Adjustment Mechanism (CBAM) similar to the EU’s version—but with a key advantage: American steel is already green.

This simple yet powerful model has worked effectively:

Tariff Protection → Higher Profit Margins → Reinvestment in Green Projects

In contrast, Europe’s quota-based protections have failed to offer adequate profitability, forcing governments to fund green transitions with public money and subsidies. Yet, due to the high cost of hydrogen steel production, even those efforts are falling short.

🔧 Revolutionizing Metal Fabrication: How Digital Twins and IoT Are Shaping the Future of Steel Manufacturing

The steel and metal industries are entering an era marked by rapid transformation—driven by technological evolution, rising global demand, and an urgent push toward sustainability. With growing pressure to minimize environmental footprints and adopt smarter practices, manufacturers are embracing digitalization at an unprecedented pace. Automation, AI, and data-driven technologies are redefining precision in metal fabrication.

Global demand for metals and specialty steel is expected to remain robust in 2025, fueled by the boom in infrastructure, construction, electric vehicles, and renewable energy sectors. These demands are compelling metal producers to upgrade production capabilities, streamline operations, and invest in next-gen technologies that ensure efficiency, quality, and agility.

One of the most game-changing developments in this transition is the rise of Digital Twin and Industrial Internet of Things (IIoT)—technologies that are radically transforming how manufacturers design, simulate, operate, and optimize their processes.

🧠 What Is Digital Twin Technology in Manufacturing?

A Digital Twin is a real-time, virtual replica of a physical object, machine, or entire system. It enables manufacturers to simulate, monitor, and optimize operations remotely without physically interacting with the equipment. Whether it’s a machine, production line, or a whole plant, digital twins allow for performance tracking, predictive maintenance, and operational innovation.

Originally tied to product lifecycle management, digital twins have evolved significantly—especially with the emergence of Industry 4.0, which emphasizes automation, interconnectivity, and real-time data analytics.

The adoption of digital twins is growing fast, helping manufacturers build smarter, leaner, and more responsive production environments. With this technology, businesses can now predict system failures, reduce downtime, and accelerate product development through simulation and optimization.

🌐 The Role of IoT in Steel and Metal Manufacturing

The Internet of Things (IoT) is equally transforming the metal production and distribution ecosystem. IoT-enabled devices and sensors capture data across all stages—from raw material handling to final product delivery—ensuring transparency, efficiency, and responsiveness.

Key IoT applications in metal manufacturing include:

- Real-time Equipment Monitoring: Sensors track machine performance, temperature, humidity, and vibration to maintain safe operational thresholds and reduce unplanned downtime.

- Smart Inventory Management: Automated systems predict stock levels, trigger restocking processes, and eliminate delays due to material shortages.

- Logistics and Distribution Optimization: Technologies like GPS and RFID enable real-time shipment tracking, enhancing supply chain visibility and ensuring timely, accurate deliveries.

Together, Digital Twins and IoT create a connected, intelligent production framework that’s transforming the traditional metal industry into a digital-first powerhouse.

🔄 Digital Twins vs Traditional Simulation Models

Traditional simulation models are based on static, pre-set scenarios using historical data. In contrast, digital twins are dynamic and real-time, continuously fed by live operational data. This distinction allows digital twins to support predictive and prescriptive analytics, making them far more powerful and actionable.

Types of Digital Twins in Manufacturing:

- Product Twins

- Simulate the behavior of individual components or products.

- Useful in performance tracking and lifecycle optimization (e.g., EV battery health).

- Production Twins

- Mirror entire production lines or factory floors.

- Optimize plant layout and reduce workflow bottlenecks.

- Performance Twins

- Monitor system-wide performance and recommend real-time adjustments.

- Example: A power plant optimizing energy output and reducing inefficiencies.

🔩 Real-World Applications of Digital Twins in Manufacturing

1. Design & Prototyping

- Digital twins reduce the reliance on physical prototypes by enabling virtual testing, significantly lowering time-to-market and R&D costs.

2. Production Planning

- Virtually simulate different layout and workflow configurations to discover the most efficient paths for material flow, manpower, and resource allocation.

3. Real-Time Monitoring

- Live data integration allows immediate detection of issues and implementation of corrective actions before disruptions occur.

4. Equipment Management

- Enables real-time condition monitoring, supports predictive maintenance, and enhances performance tuning to extend equipment life.

5. Training & Safety

- Offers immersive, hands-on simulation environments for staff training and operational safety.

6. Tours & Stakeholder Engagement

- Create interactive digital experiences for visitors, clients, and investors—offering a transparent look into operational excellence and innovation.

7. Marketing, Planning & Sustainability

- Demonstrates your company’s commitment to innovation and environmental consciousness, strengthens your brand, and helps reduce design flaws and rework.

🚀 Advantages of Adopting Digital Twins in Metal Fabrication

Digital twins are not just another tech trend—they deliver measurable value across all areas of the manufacturing lifecycle. Here’s how:

- Process Optimization: Digital twins help fine-tune manufacturing workflows, minimize waste, and maximize throughput.

- Predictive Maintenance: Real-time monitoring enables early detection of anomalies, preventing costly breakdowns and extending machine life.

- Data-Driven Decision Making: Access to real-time analytics allows leaders to make smarter, faster business decisions.

- Training & Simulation: Operators can practice in virtual environments, reducing on-the-job learning curves and improving safety.

- Stakeholder Engagement: Digital twins offer visual insights into factory operations, improving transparency and inspiring investor confidence.

💭 What the World Can Learn

The U.S. model demonstrates that green transformation doesn’t have to wait for perfect hydrogen technology or multi-billion subsidies. Instead, it requires:

- Strategic investments in proven technologies (EAF, DRI, CCS)

- Reliable domestic scrap collection

- Clear regulatory support and market protection

- Real innovation like modular nuclear and fusion energy, and CO₂ mineralization

By aligning industry interests with policy incentives and consumer expectations, the United States has built the world’s most competitive green steel market.

🔚 Conclusion: The Future is Smart, Connected, and Sustainable

As we move toward 2025 and beyond, the steel and metal industries must evolve to remain competitive. Embracing Digital Twin and IoT technology will no longer be optional—it will be essential for manufacturers seeking to improve efficiency, meet customer expectations, and comply with stricter environmental standards.

With predictive power, real-time analytics, and seamless integration, these technologies unlock new frontiers in metal manufacturing. Organizations that invest in them today will gain resilience, innovation, and a competitive edge tomorrow.

At LUX METAL, we are committed to leading this transformation—helping clients modernize their processes with precision metal solutions that are smarter, leaner, and greener.

📞 Get in touch today to discover how we can support your journey into the future of metal manufacturing.

🌐 Visit: www.luxmetalgroup.com

🌍 A Blueprint for Malaysia’s Steel Future?

At LUX METAL, we see massive opportunity for Malaysia to leap ahead in Southeast Asia’s green steel revolution—not by reinventing the wheel, but by learning from the American success formula:

✅ Prioritize scrap-based production and invest in recycling

✅ Adopt modular, scalable EAF technologies

✅ Encourage local R&D in CO₂ reduction and capture

✅ Align government policy with industrial needs and trade protection

✅ Educate the market on the value of low-carbon steel

🔧 Building a Greener Tomorrow — With Steel That Works

As Malaysia’s trusted metal fabrication partner, LUX METAL is committed to sustainability, innovation, and strategic growth. We believe in creating real solutions—efficient, practical, and scalable—just like America’s green steel path.

📩 Reach out to collaborate on sustainable steel projects

🌐 Visit us: www.luxmetalgroup.com

🏗️ About LUX METAL

LUX METAL is Malaysia’s trusted expert in customized steel and stainless-steel fabrication, offering end-to-end solutions from design to delivery. With state-of-the-art equipment—including CNC laser cutting, bending, sheet rolling, V-cutting, and precision welding—we bring innovation and craftsmanship to every project.

Whether you’re prototyping a concept, scaling production, or seeking sustainable solutions for your next build, our team is ready to deliver.

🔗 Visit us at www.luxmetalgroup.com to discover how LUX METAL can power your vision into reality.

📚 References

To explore more on the evolution of green steel production and how emerging technologies like Digital Twins and IoT are reshaping the metal industry, check out these insightful sources: