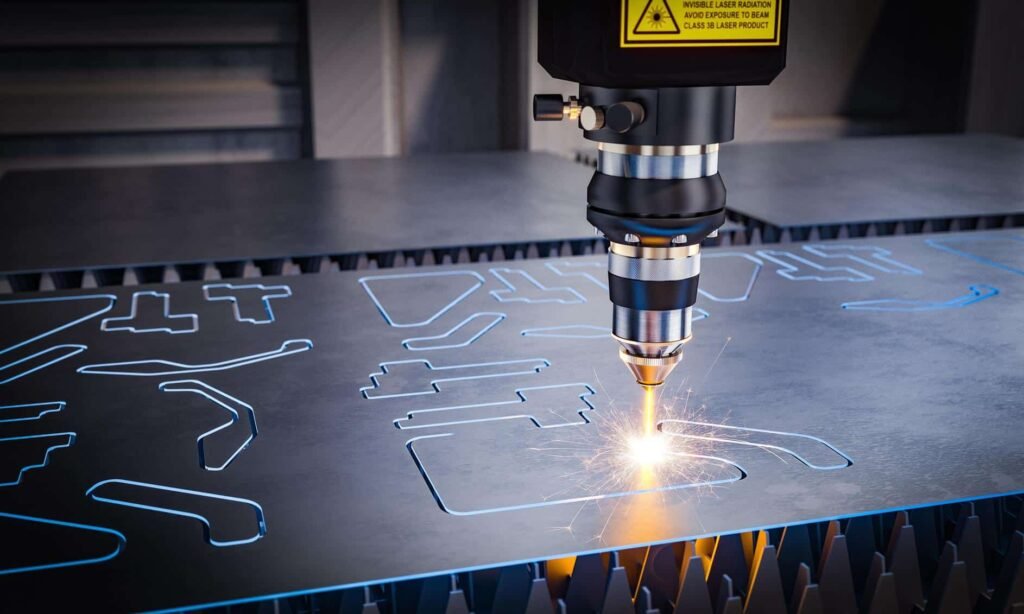

What Is Laser Cutting?

Laser cutting is a technology that uses a high-powered laser beam to slice through materials with exceptional accuracy. The process involves directing a concentrated beam of light, often guided by computer numerical control (CNC) systems, to cut or engrave materials such as metal, wood, acrylic, and even fabrics. The laser beam melts, burns, or vaporizes the material along its path, creating clean and precise edges.

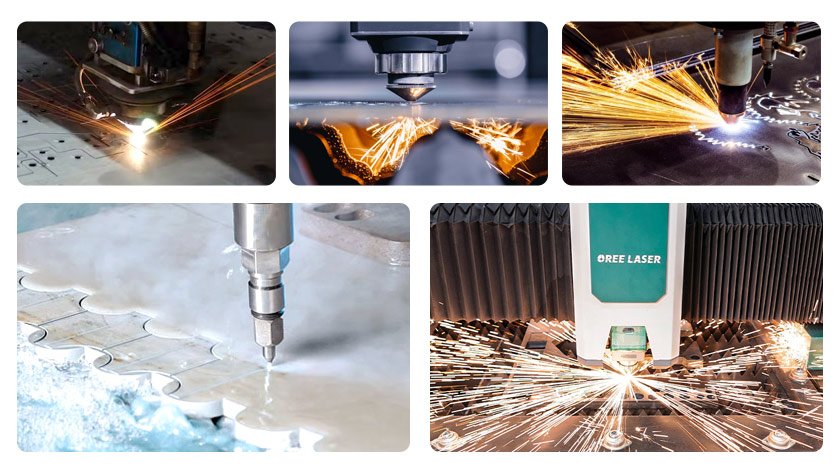

The technology is categorized into three main types:

- CO2 Laser Cutting: Ideal for non-metallic materials such as wood, acrylic, and paper.

- Fiber Laser Cutting: Specializes in cutting metals, including stainless steel, aluminum, and brass.

- Crystal Laser Cutting: Used for high-power applications and materials like ceramics or thicker metals.

Reference: https://www.3ds.com/make/guide/process/laser-cutting

Applications of Laser Cutting

1. Industrial Manufacturing

Laser cutting is a staple in industrial production, particularly in the automotive and aerospace industries. It allows for the fabrication of complex components with minimal material wastage. Parts such as engine components, chassis, and custom brackets are efficiently produced with tight tolerances.

2. Architecture and Construction

Architects and designers use laser cutting to create intricate designs on materials like metal panels and glass. These elements are often incorporated into façades, interior designs, and decorative structures.

3. Creative Arts and Crafts

Artists and hobbyists leverage laser cutting for detailed work on paper, wood, and acrylic. From custom jewelry to elaborate art installations, the possibilities are endless.

4. Electronics

In electronics, laser cutting is used to produce intricate circuit boards, casings, and small components essential for modern devices.

5. Fashion and Textiles

Laser technology is transforming the fashion industry by enabling precise cuts in fabrics, leather, and synthetic materials. Designers can create intricate patterns and unique textures that would be challenging to achieve manually.

Advantages of Laser Cutting

1. Precision and Accuracy

One of the standout features of laser cutting is its ability to produce highly accurate cuts with tolerances as tight as 0.1 mm. This level of precision is crucial for applications requiring intricate designs or exact specifications.

2. Speed and Efficiency

Laser cutting significantly reduces production time compared to traditional methods. High-speed laser systems can handle large-scale projects efficiently, making it ideal for industrial applications.

3. Versatility

Laser cutters can process a wide range of materials, from delicate fabrics to sturdy metals. This flexibility allows manufacturers and artists to experiment with different materials without investing in multiple tools.

4. Minimal Waste

The focused nature of laser beams ensures minimal material wastage. This is not only cost-effective but also environmentally friendly, aligning with sustainable manufacturing practices.

5. Reduced Post-Processing

Cuts made by lasers are often clean and smooth, requiring little to no additional finishing. This reduces labor costs and speeds up the production process.

Challenges and Limitations

While laser cutting offers numerous benefits, it’s not without its challenges:

- High Initial Cost: The upfront investment in laser cutting machines can be substantial.

- Material Limitations: Some materials, like certain reflective metals, can be challenging to cut.

- Maintenance: Laser systems require regular maintenance to ensure optimal performance.

- Health and Safety: Proper ventilation and safety measures are necessary to handle fumes and laser radiation.

Emerging Trends in Laser Cutting

1. Automation and AI Integration

The integration of AI and automation is streamlining laser cutting processes. Smart systems can optimize cutting paths, predict wear and tear, and even perform self-diagnostics.

2. Green Laser Technology

Eco-friendly laser systems are gaining traction, offering energy-efficient operations and lower emissions. These advancements align with global sustainability goals.

3. Hybrid Manufacturing

Combining laser cutting with other technologies, such as 3D printing, is opening new avenues in manufacturing and design. Hybrid systems offer unparalleled flexibility and innovation.

4. Advancements in Material Science

The development of new materials compatible with laser cutting, such as ultra-thin metals and bio-based polymers, is expanding its applications.

How to Choose the Right Laser Cutter

Selecting the right laser cutter depends on your specific needs. Here are some factors to consider:

- Material Type: Determine the primary materials you’ll be working with.

- Power Requirements: Higher power is required for thicker or harder materials.

- Bed Size: Ensure the machine can accommodate the dimensions of your projects.

- Software Compatibility: Opt for systems that integrate seamlessly with your design software.

- Budget: Balance features with cost to find a machine that offers the best value.

Reference:Which machine is best for cutting?

Laser Cutting in the Future

As technology advances, laser cutting is poised to become even more integral to manufacturing and design. With innovations in speed, precision, and environmental sustainability, the potential applications are limitless. Industries will continue to push the boundaries, using laser technology to create smarter, more efficient, and aesthetically striking products.

Laser cutting isn’t just a tool; it’s a game-changer. Whether you’re an industrial manufacturer, an architect, or an artist, this technology offers a world of possibilities. By harnessing its power, you can bring your most intricate ideas to life with unmatched precision and efficiency.

Partner with Lux Metal for Premium Steel Solutions

For businesses seeking high-quality steel products and customized metal solutions, Lux Metal is your trusted partner. Visit our website to explore our wide range of services and see how we can help you meet your industrial needs with precision and excellence.