Who We Are

We are metal fabricator in Malaysia. At LUX METAL, we specialize in providing tailored metal fabrication solutions for industries such as construction, automotive, aerospace, electronics, and more. With years of experience in the industry, we have honed our processes to ensure precision, durability, and cost-effectiveness in every project we undertake.

Our commitment to quality, innovation, and customer satisfaction has made us a trusted partner for businesses both locally and internationally. Whether you need custom parts, large-scale production runs, or prototype development, we have the expertise and tools to bring your vision to life.

Our Comprehensive Range of Machinery

One of the key reasons behind our success is our investment in a comprehensive range of advanced machinery. We understand that precision and efficiency are critical in metal fabrication, which is why we rely on cutting-edge equipment, including:

1. CNC Machines

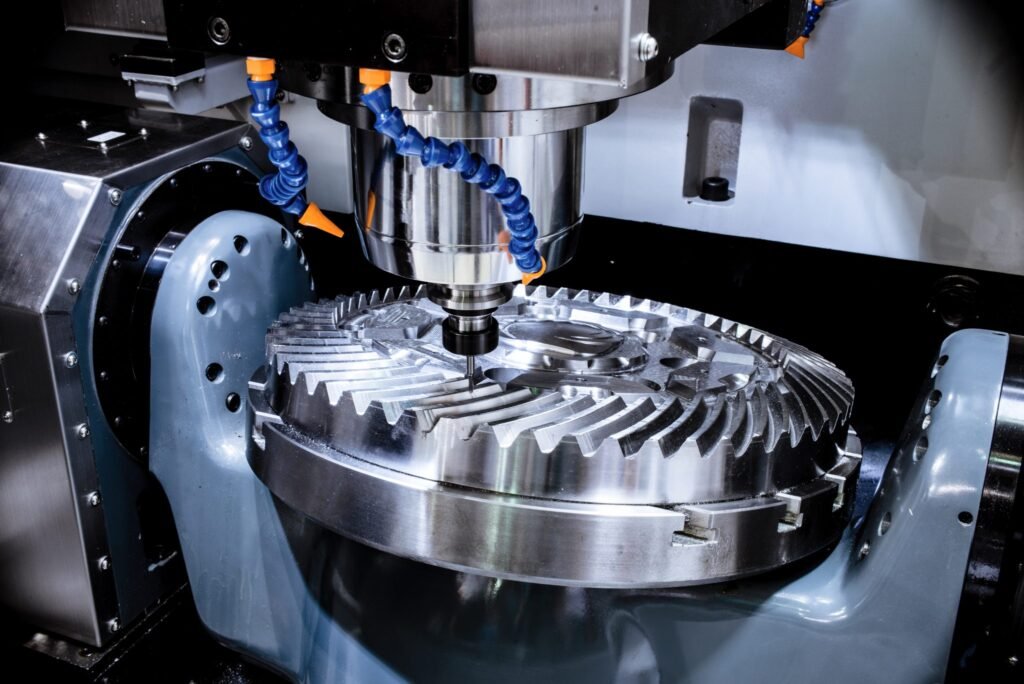

Computer Numerical Control (CNC) technology revolutionized the metal fabrication industry, enabling us to achieve unmatched accuracy and consistency. Our CNC machines are equipped to handle a variety of processes, including:

- CNC Milling: Perfect for creating intricate shapes and designs with tight tolerances.

- CNC Turning: Ideal for cylindrical components, ensuring smooth finishes and precise dimensions.

- CNC Drilling: High-speed, accurate drilling for both small and large-scale projects.

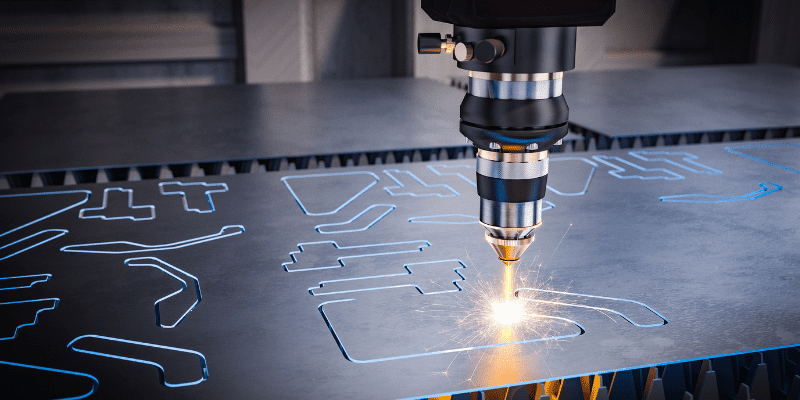

- CNC Cutting: Laser, plasma, or waterjet cutting for clean, precise cuts on various metal types.

Our CNC machines allow us to handle complex geometries and intricate designs that traditional machinery cannot achieve.

CNC LASER CUTTING MACHINE

CNC MILLING MACHINE

CNC PIPING MACHINE

2. Metal Sheet Machines

Sheet metal fabrication is a cornerstone of our operations, and our advanced machinery ensures that we deliver high-quality results, whether you need simple brackets or intricate enclosures. Key equipment in our lineup includes:

- Laser Cutting Machines: For high-speed, precise cutting of sheet metal, ideal for producing detailed patterns and minimizing waste.

- Press Brakes: For accurate bending and shaping of sheet metal, crucial for creating components like panels and brackets.

- Shearing Machines: Efficient for cutting sheet metal into desired sizes with clean edges.

- Punching Machines: Designed to create holes, slots, and other features with precision.

By combining the capabilities of our sheet metal machinery with skilled craftsmanship, we can produce components that meet even the most stringent specifications.

Why Choose LUX METAL?

When it comes to metal fabrication in Malaysia, we set ourselves apart in several ways:

1. Cutting-Edge Technology

We constantly invest in the latest machinery and software to stay ahead of industry trends. Our use of advanced CNC and sheet metal machines ensures that we can handle projects with high levels of precision and efficiency.

2. Versatility

Our diverse range of machinery allows us to work with various materials, including stainless steel, aluminum, brass, and mild steel. Whether you need lightweight components for the aerospace industry or heavy-duty parts for construction, we have the tools and expertise to deliver.

3. Customized Solutions

No two projects are the same, which is why we offer fully customized solutions tailored to your specific needs. Our team works closely with clients to understand their requirements and deliver products that exceed expectations.

4. Quality Assurance

We adhere to strict quality control standards at every stage of production. From initial design to final delivery, we ensure that every component meets industry standards and client specifications.

5. Experienced Team

Our team of skilled engineers, machinists, and technicians bring years of experience to the table. Their expertise allows us to tackle even the most complex projects with confidence.

Our Process

At LUX METAL, we believe in a systematic approach to metal fabrication. Here’s how we ensure a seamless experience for our clients:

1. Consultation and Design

We begin every project with a detailed consultation to understand your requirements. Our in-house design team uses CAD/CAM software to create precise blueprints and simulations, ensuring that the final product aligns with your vision.

2. Material Selection

Choosing the right material is critical to the success of any project. We guide our clients in selecting the most suitable materials based on factors like durability, weight, and cost.

3. Fabrication

Using our advanced CNC and sheet metal machinery, we bring your designs to life. Our cutting-edge technology ensures accuracy, efficiency, and minimal waste.

4. Quality Control

Before delivery, every component undergoes rigorous quality checks to ensure it meets our high standards. We use advanced inspection tools to verify dimensions, finishes, and structural integrity.

VMM Machine

5. Delivery and Support

We offer flexible delivery options to meet your deadlines and provide ongoing support to ensure your complete satisfaction.

Industries We Serve

Our services cater to a wide range of industries, including:

- Construction: Custom metal components for buildings, infrastructure, and machinery.

- Automotive: Precision parts for vehicles, including prototypes and production runs.

- Aerospace: Lightweight, high-strength components for aircraft.

- Electronics: Enclosures, brackets, and other components for electronic devices.

- Oil and Gas: Durable parts for pipelines, rigs, and equipment.

- Pharmaceutical: Filter housings, storage containers, laboratory vessels, sterilizer vessels, and other complex assemblies.

No matter your industry, our expertise and technology enable us to deliver solutions that drive success.

Sustainability and Innovation

As a responsible metal fabricator, we are committed to sustainability. Our processes are designed to minimize waste, and we prioritize the use of recyclable materials whenever possible. Additionally, we continuously explore innovative techniques and technologies to improve efficiency and reduce our environmental impact.

Partner with Us Today

At LUX METAL, we take pride in being a trusted partner for metal fabrication in Malaysia. With our comprehensive range of machinery, skilled team, and dedication to quality, we are ready to tackle your next project with precision and professionalism.

Whether you’re looking for a one-time production run or a long-term partnership, we’re here to help. Contact us today to learn more about our services and how we can bring your ideas to life.

For manufacturing companies in Malaysia seeking high-quality, customized metal solutions, Lux Metal offers a full suite of stainless steel fabrication services designed to enhance efficiency and meet the rigorous standards of today’s market.