Understanding OEM Mechanical Assembly

OEM (Original Equipment Manufacturer) machine assembly refers to the process of assembling machines or equipment according to the specifications of an OEM company. In this model, the OEM designs the machine, while the assembly is either done in-house or outsourced to specialized manufacturers who follow strict quality and compliance guidelines.

OEM machine assembly is crucial for industries such as automotive, aerospace, medical devices, and industrial machinery, ensuring that products meet precise engineering requirements, safety standards, and performance expectations. This process allows OEMs to focus on design and innovation while relying on expert assemblers to handle production efficiently.

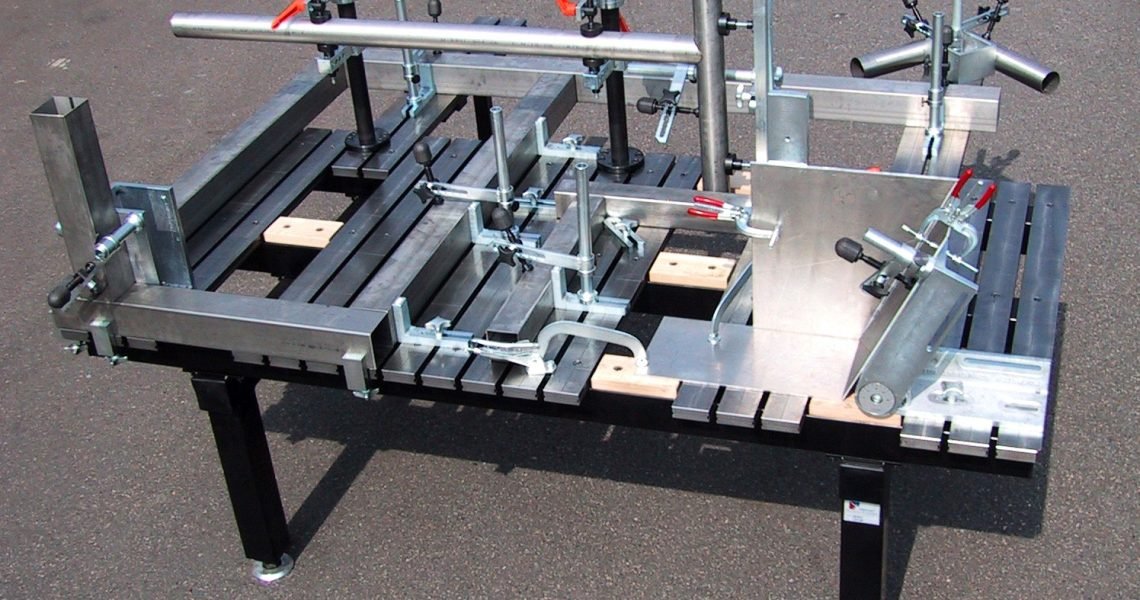

Mechanical assembly refers to the process of systematically bringing together mechanical and electronic components, such as fasteners, bearings, shafts, motors, hydraulic systems, and control units, to create a fully functional machine. Depending on the complexity of the machine, assembly can be manual, semi-automated, or fully automated. Each approach requires precision to prevent misalignment, operational inefficiencies, and potential failures that can arise from poor assembly practices.

Reference: https://luxmetalgroup.com/machine-assembly/

Types of Mechanical Assembly

Mechanical assembly can be broadly classified into the following categories:

- Manual Assembly: Performed by skilled technicians using hand tools and specialized instruments. This approach is common in small-scale production or custom-built machinery.

- Semi-Automated Assembly: Involves a combination of human labor and automated machinery to enhance accuracy and efficiency.

- Fully Automated Assembly: Utilizes robotics, computer-controlled systems, and high-precision machinery to complete assembly tasks with minimal human intervention.

Regardless of the approach, successful machine assembly requires adherence to strict quality standards and engineering specifications to ensure reliability and efficiency.

Key Stages of Machine Assembly

1. Preparation and Planning

- Review detailed engineering drawings, blueprints, and assembly instructions.

- Verify that all required parts, tools, and equipment are readily available.

- Inspect individual components for manufacturing defects, dimensional accuracy, and material integrity.

- Ensure that the work environment is clean, organized, and optimized for safe assembly.

2. Subassembly Construction

- Assemble smaller functional units or modules before integrating them into the final system.

- Conduct preliminary quality checks and functionality tests to ensure proper operation.

- Verify that subassemblies meet precise tolerances and alignments as specified in the design.

3. Final Assembly

- Integrate subassemblies into the main structure of the machine.

- Secure fasteners, align moving parts, and connect power, hydraulic, or pneumatic systems.

- Adjust components for proper fitment and smooth operation.

- Implement lubrication, wiring, and insulation as per safety requirements.

References: Semi-Modular & Final Assembly

4. Testing and Quality Control

- Perform rigorous operational testing to ensure all components function correctly.

- Inspect for mechanical alignment, structural integrity, lubrication, and electrical connectivity.

- Conduct load testing and stress analysis to verify the machine’s performance under real-world conditions.

- Document test results and make necessary refinements before final approval and commissioning.

Challenges in Mechanical Assembly

The process of assembling complex machinery comes with several challenges that need to be addressed:

- Precision and Tolerances: Even minor deviations can lead to mechanical inefficiencies, excessive wear, or complete failure of the machine.

- Material Handling: Heavy and intricate components require specialized lifting and positioning equipment to ensure safe and accurate assembly.

- Workforce Skill Requirements: Proper training and experience are essential for assembling complex machines while adhering to technical specifications.

- Compliance with Safety and Industry Standards: Adhering to international standards such as ISO, ASME, and ANSI ensures safety, reliability, and legal compliance.

- Component Compatibility: Ensuring that all parts fit together as designed is crucial to prevent performance issues and costly rework.

Best Practices for Efficient Machine Assembly

To optimize the mechanical assembly process, manufacturers must adopt best practices that enhance precision, efficiency, and reliability:

- Standardized Assembly Procedures: Establish clear and detailed assembly instructions to maintain consistency and reduce errors.

- Use of Advanced Tools and Equipment: High-precision instruments, torque wrenches, and automation tools improve accuracy and reduce human error.

- Quality Assurance at Every Stage: Implement stringent inspection and testing protocols throughout the assembly process.

- Proper Documentation: Maintain comprehensive records of assembly procedures, test results, and quality checks to ensure traceability and continuous improvement.

- Continuous Workforce Training: Regular training programs help workers stay updated with the latest assembly techniques, tools, and industry standards.

- Lean Manufacturing Principles: Streamlining workflows and minimizing waste enhances overall productivity and cost-effectiveness.

The Role of Automation in Modern Assembly

With advancements in Industry 4.0, automation and digitalization are revolutionizing the mechanical assembly process. Robotics, AI-powered inspection systems, and IoT-enabled monitoring tools are increasingly being integrated into assembly lines to enhance precision and efficiency. Some key benefits of automation in mechanical assembly include:

- Increased Speed and Efficiency: Automated systems can perform repetitive tasks faster and with higher accuracy than manual assembly.

- Improved Quality Control: Advanced sensors and AI-driven inspections help detect defects and deviations in real time.

- Reduced Human Error: Automation minimizes reliance on manual labor, reducing inconsistencies and errors.

- Enhanced Safety: Robotic assembly reduces workplace hazards associated with heavy lifting and repetitive tasks.

- Scalability: Automated assembly lines can be easily scaled to accommodate production volume changes without compromising quality.

Conclusion

Mechanical machine assembly is a crucial aspect of industrial manufacturing, requiring a blend of technical expertise, precision engineering, and strict quality control measures. By leveraging best practices, advanced tools, and automation technologies, manufacturers can achieve higher efficiency, reduce downtime, and ensure the longevity of their machines. Whether assembling simple mechanical systems or complex industrial equipment, a structured and methodical approach will lead to superior performance, safety, and reliability.

As industries continue to evolve, embracing innovations in mechanical assembly will be essential for staying competitive in the global market. Investing in skilled labor, modern technology, and stringent quality assurance measures will not only enhance assembly efficiency but also contribute to long-term operational succes

For more information, visit our website for OEM Machine Assembly Services: https://luxmetalgroup.com/machine-assembly/

At Lux Metal, We specialize in providing customized machine assembly services tailored to meet the unique needs of our clients. Our team of experts ensures that every assembled machine adheres to the highest quality standards, including ISO and industry-specific certifications. By implementing rigorous quality control measures and precision engineering, we guarantee that our assembled machines deliver exceptional performance, reliability, and compliance with global manufacturing regulations.