Aircraft Construction

- Structural Components: Stainless steel is widely used in the structural framework of aircraft. Its high strength-to-weight ratio allows for robust construction while keeping the aircraft light, essential for fuel efficiency and performance.

- Landing Gear: The landing gear must withstand immense stress during takeoff, landing, and taxiing. Stainless steel’s durability and resistance to impact make it an ideal material for these components.

- Exhaust Systems: Aircraft exhaust systems operate at high temperatures and are exposed to corrosive gases. Stainless steel’s heat resistance and anti-corrosive properties ensure longevity and reliability in these harsh conditions.

- Fasteners and Fittings: Stainless steel fasteners and fittings are critical in maintaining the integrity of the aircraft’s structure. They provide secure connections and resist loosening under vibration and thermal expansion.

Space Exploration

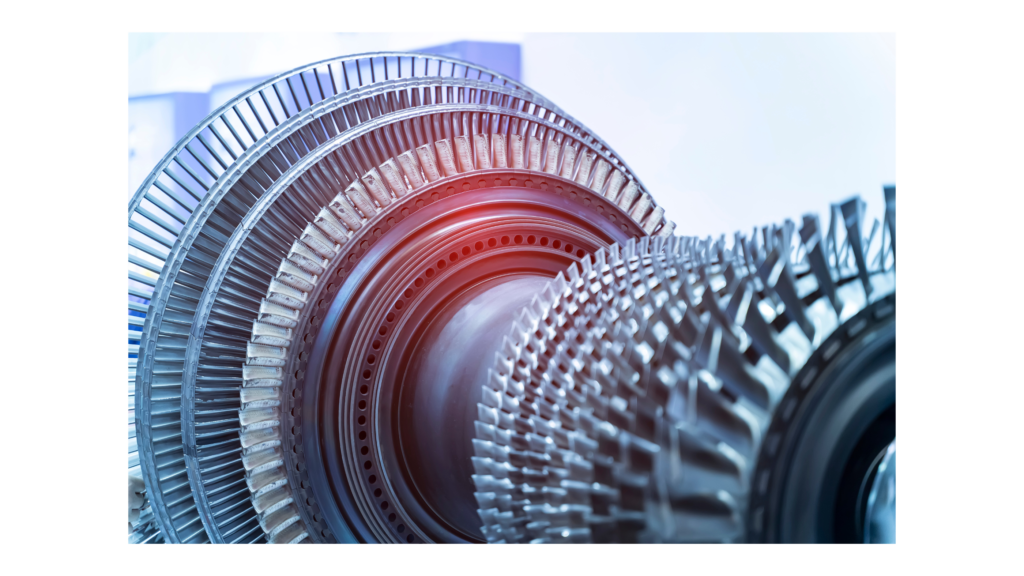

- Rocket Engines: Rocket engines operate under extreme temperatures and pressures. Stainless steel is used in various engine components, such as combustion chambers and nozzles, due to its ability to maintain strength and stability in these environments.

- Spacecraft Frames: The frame of a spacecraft must be both lightweight and incredibly strong to survive the forces of launch and the vacuum of space. Stainless steel offers the perfect combination of properties to meet these demands.

- Fuel Tanks: Stainless steel is used in the construction of fuel tanks for its ability to resist chemical corrosion and maintain structural integrity, ensuring the safe storage and transport of highly reactive propellants.

Satellite Technology

- Satellite Bodies: The body of a satellite, or bus, houses all the satellite’s instruments and systems. Stainless steel is used for its strength and ability to shield sensitive electronics from radiation and impact damage.

- Solar Panel Frames: Solar panels on satellites require robust frames that can withstand the harsh conditions of space. Stainless steel provides a sturdy and corrosion-resistant solution, ensuring the panels remain functional over long missions.

- Antenna Structures: Communication satellites rely on antennas to transmit signals. Stainless steel is often used in these structures for its durability and precision in maintaining alignment and function over time.

The Benefits of Stainless Steel in the Aerospace Industry

Stainless steel is an indispensable material in the aerospace industry, where reliability, strength, and resistance to extreme conditions are paramount. Its unique properties make it ideal for various applications, from aircraft construction to space exploration and satellite technology. This blog post explores the numerous benefits of stainless steel in the aerospace industry, highlighting its critical role in advancing aerospace engineering.

Strength and Durability

Stainless steel is renowned for its high strength-to-weight ratio, making it an excellent choice for structural components in aerospace engineering. This property ensures that aircraft and spacecraft can withstand the immense forces and stresses experienced during takeoff, flight, and landing while maintaining a lightweight structure for fuel efficiency and performance.

- Aircraft Frames: The structural framework of aircraft benefits greatly from stainless steel’s strength, providing a robust and reliable foundation that enhances the safety and durability of the aircraft.

- Rocket Engines: Stainless steel is used in rocket engine components such as combustion chambers and nozzles. Its ability to maintain strength and stability under extreme temperatures and pressures is crucial for the success of space missions.

Corrosion Resistance

One of the standout properties of stainless steel is its exceptional resistance to corrosion. Aerospace components are frequently exposed to harsh environments, including salty air, high humidity, and corrosive chemicals. Stainless steel’s corrosion resistance ensures the longevity and reliability of these components, reducing maintenance costs and enhancing safety.

- Landing Gear: The landing gear of aircraft must withstand exposure to various environmental conditions, including de-icing chemicals and salty air. Stainless steel’s corrosion resistance makes it an ideal material for these components.

- Fuel Tanks: In spacecraft, stainless steel fuel tanks resist chemical corrosion and maintain structural integrity, ensuring the safe storage and transport of highly reactive propellants.

Heat Resistance

The aerospace industry demands materials that can perform reliably under extreme temperatures. Stainless steel’s heat resistance makes it suitable for applications where components are exposed to high temperatures, such as in aircraft exhaust systems and rocket engines.

- Exhaust Systems: Aircraft exhaust systems operate at high temperatures and are exposed to corrosive gases. Stainless steel’s heat resistance and anti-corrosive properties ensure longevity and reliability in these harsh conditions.

- Spacecraft Frames: The frame of a spacecraft must be both lightweight and incredibly strong to survive the forces of launch and the vacuum of space. Stainless steel offers the perfect combination of properties to meet these demands.

Versatility and Adaptability

Stainless steel’s versatility allows it to be used in various forms and for multiple applications within the aerospace industry. From fasteners and fittings to complex structural components, stainless steel can be adapted to meet the specific needs of different aerospace projects.

- Fasteners and Fittings: Stainless steel fasteners and fittings are critical in maintaining the integrity of the aircraft’s structure. They provide secure connections and resist loosening under vibration and thermal expansion.

- Antenna Structures: Communication satellites rely on antennas to transmit signals. Stainless steel is often used in these structures for its durability and precision in maintaining alignment and function over time.

Sustainability and Cost-Effectiveness

Stainless steel is not only a high-performing material but also a sustainable one. It is 100% recyclable, which reduces the environmental impact of aerospace manufacturing. Additionally, its durability and low maintenance requirements make it a cost-effective choice for aerospace applications.

- Recyclability: Stainless steel’s ability to be recycled without loss of properties makes it an environmentally friendly option for the aerospace industry.

- Low Maintenance: The durability and corrosion resistance of stainless steel reduce the need for frequent maintenance and replacements, leading to lower lifecycle costs.

Conclusion

Stainless steel’s unique properties make it indispensable in the aerospace industry, where reliability, strength, and performance are paramount. From aircraft construction to space exploration and satellite technology, stainless steel ensures that critical components can withstand the most challenging environments. Its continued use in aerospace engineering will undoubtedly contribute to future advancements and innovations in the industry.

As the industry continues to advance, stainless steel will remain a critical material, supporting innovations in aircraft construction, space exploration, and satellite technology. For more information on the benefits of stainless steel in aerospace applications, visit Choong Ngan Engineering.

For more information on how stainless steel can benefit your aerospace projects or to discuss custom solutions, visit our website at Lux Metal Group. Our expertise in stainless steel fabrication ensures that we can meet the stringent requirements of the aerospace industry with precision and excellence.