What Are Steel Beams?

Steel beams are horizontal structural elements designed to resist loads applied laterally to the beam’s axis. They play a crucial role in supporting structures and ensuring their stability and safety. These beams are commonly used in construction due to their strength, versatility, and ability to withstand substantial weight.

Steel beams are often preferred over other materials due to their high strength-to-weight ratio, which allows them to support more load with less material. This efficiency not only saves on costs but also reduces the overall weight of the structure, which can be particularly beneficial in high-rise buildings and long-span bridges.

Common Advantages of Steel Beams

Steel beams offer several advantages, making them a popular choice in construction:

- Strength and Durability: Steel beams are incredibly strong and can support heavy loads, making them ideal for large buildings and structures. Their high tensile strength means they can withstand significant tension and compression without bending or breaking.

- Versatility: Steel beams can be used in various applications, from residential buildings to commercial skyscrapers, and are available in different shapes and sizes to meet specific construction needs. This adaptability makes them suitable for a wide range of architectural designs and engineering requirements.

- Cost-Effectiveness: Due to their strength, fewer beams are needed to achieve the same support as other materials, reducing both material and labor costs. Additionally, steel beams can be prefabricated and assembled quickly, further lowering construction time and expenses.

- Sustainability: Steel is one of the most recyclable materials available, and steel beams can often be reused in other projects or recycled into new steel products, making them an environmentally friendly option for construction projects. Using steel reduces the need for new raw materials and minimizes waste, contributing to more sustainable building practices.

- Fire Resistance: Unlike wood, steel beams do not contribute to the spread of fire. They maintain their structural integrity under high temperatures for longer periods, providing valuable time for evacuation and firefighting efforts. This property is particularly important in buildings where safety is a paramount concern.

- Ease of Maintenance: Steel beams require minimal maintenance once installed. They are resistant to pests, rot, and other forms of degradation that can affect other materials like wood. This durability reduces the long-term costs associated with maintenance and repair.

The Differences Between Steel Columns and Beams

While both steel columns and beams are essential in construction, they serve different purposes:

- Steel Columns: Vertical structural elements designed to carry compressive loads. They transfer the weight of the structure above to the foundation below, preventing the building from collapsing. Columns are critical in ensuring that loads are evenly distributed throughout a structure.

- Steel Beams: Horizontal elements that primarily resist bending under loads. Beams support the weight of floors, roofs, and other horizontal surfaces, distributing these loads to the columns and foundations. They are essential for maintaining the structural integrity and stability of buildings.

Understanding the difference between columns and beams is crucial for selecting the right component for your construction project. The proper combination of beams and columns ensures that a building can support its own weight and any additional loads it may encounter, such as occupants, furniture, and equipment.

Classification of Steel Beams in Construction

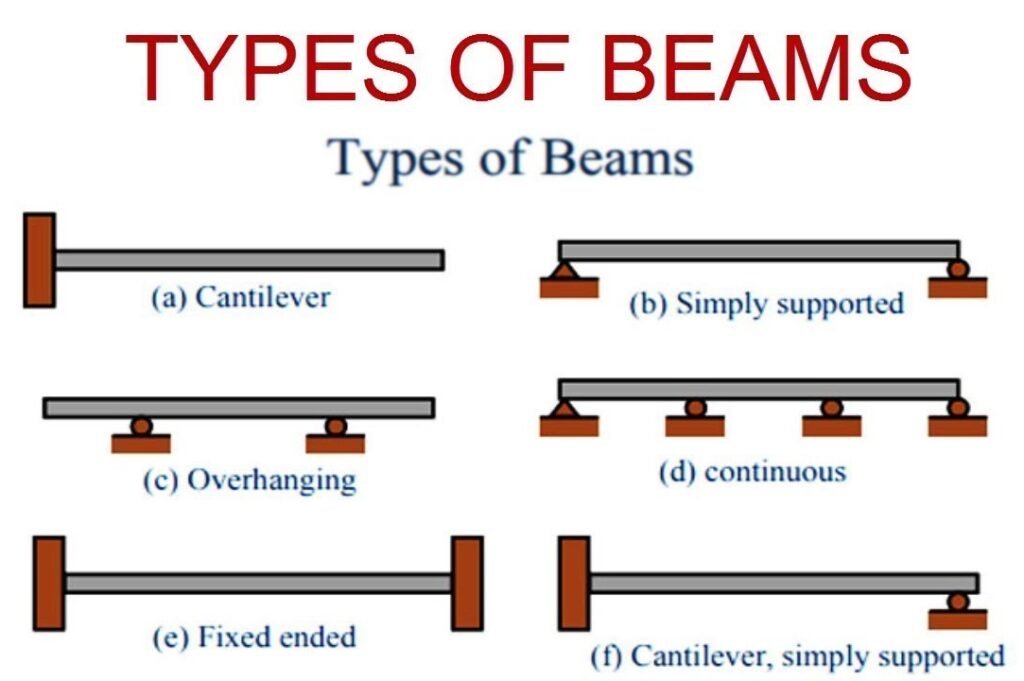

Classification Based on Support:

- Simply Supported Beams: Supported at both ends, commonly used in bridges and buildings. These beams are straightforward in design and are often used where the load is evenly distributed.

- Fixed Beams: Fixed at both ends, providing more rigidity and support. These beams are ideal for situations where minimal deflection is required, such as in structural frames that need to resist horizontal forces like wind or seismic activity.

- Composite Beams: Combine materials, such as steel and concrete, for enhanced strength. The combination of materials allows for the distribution of loads between the steel and concrete, maximizing the benefits of both materials and providing greater resistance to bending and shear forces.

- Cantilever Beams: Supported at one end only, ideal for overhanging structures such as balconies or canopies. Cantilever beams can support loads without requiring external bracing or support, making them useful in architectural designs where unobstructed views or spaces are desired.

- Continuous Beams: Extend over multiple supports, reducing bending moments and deflection. These beams are commonly used in long-span applications, such as bridges and large buildings, where continuous support is available.

- Over-Hanging Beams: Extend beyond supports, used in specific architectural designs to create extended overhangs or awnings. Over-hanging beams provide additional design flexibility and can enhance the aesthetic appeal of a building.

- Double Over-Hanging Beams: Overhangs on both ends, providing additional support and design flexibility. These beams are suitable for structures that require extended support beyond the main supports, such as in cantilevered bridges or long-span roofs.

- Trussed Steel Beams: Comprised of a framework of triangles, offering superior load distribution and resistance to bending and shear forces. Trussed beams are often used in bridges and large-span roofs, where high strength and minimal deflection are required.

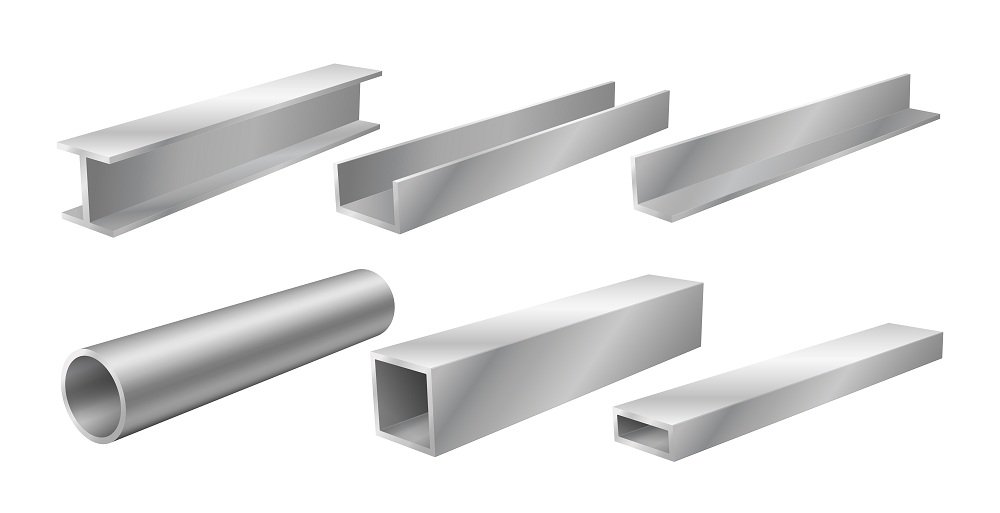

Classification Based on Cross-Section:

- I-Beams (Universal Beams): Characterized by an I-shaped cross-section, ideal for bending resistance. I-beams are commonly used in construction due to their high strength-to-weight ratio and ability to resist bending and shear forces.

- H-Beams: Similar to I-Beams but with wider flanges, providing greater surface area and strength. H-beams are often used in heavy construction applications, such as in building foundations and bridges, where additional strength and stability are required.

- W-Beams (Wide Flange Beams): Wider than I-Beams, often used in construction where large spans are required. W-beams provide greater load-bearing capacity and are commonly used in structures with wide openings or long spans.

- Channel Beams (C-Beams or U-Channels): C-shaped, typically used for minor loading applications or as secondary support members. Channel beams are often used in conjunction with other beams or structural elements to provide additional support or reinforcement.

- L-Angle Beams: L-shaped, providing support and reinforcement in frames. L-angle beams are often used in structural frames, trusses, and bracing systems to provide additional support and stability.

- T-Beams: T-shaped, used in conjunction with concrete slabs for added strength. T-beams are commonly used in construction applications where concrete and steel are combined to provide additional support and load-bearing capacity.

- Hollow Structural Sections (HSS): Hollow beams, often used in structures where weight is a concern, such as in tall buildings or structures with limited support. HSS beams provide high strength with minimal weight, making them ideal for lightweight and efficient structural designs.

- Plate Girders: Made by welding plates together, used for heavy loads and long spans. Plate girders are often used in bridges, large-span roofs, and other heavy construction applications where high strength and load-bearing capacity are required.

- Box Steel Beams: Box-shaped cross-section, providing high strength and rigidity. Box beams are commonly used in applications where torsional resistance and high strength are required, such as in tall buildings and bridges.

These various steel sections provide options for specific structural requirements and design preferences, ensuring that the right type of steel is used for the right application.

Factors to Consider When Selecting the Appropriate Steel Beam for Your Construction Project

When choosing a steel beam, consider the following:

- Load Requirements: Determine the amount of load the beam will need to support, including both dead loads (permanent, static forces) and live loads (temporary, dynamic forces).

- Beam Length and Span: The length of the beam and the distance it needs to span are crucial factors in determining the type of beam and its required strength. Longer spans may require stronger or deeper beams to support the load without excessive deflection.

- Material and Grade: Different steel grades offer various levels of strength and flexibility, depending on the application. Selecting the appropriate material and grade ensures that the beam can withstand the required loads and environmental conditions.

- Environmental Conditions: Consider the environment where the beam will be used, such as humidity, temperature, and exposure to chemicals or corrosive elements. These factors can affect the beam’s durability and performance, and appropriate coatings or treatments may be necessary to protect the beam from corrosion or degradation.

- Design and Aesthetics: The design and aesthetic requirements of the project may also influence the choice of steel beam. Curved or tapered beams, for example, may be chosen for their visual appeal or to achieve specific architectural designs.

- Budget and Cost: The cost of materials, fabrication, and installation should also be considered when selecting a steel beam. Different types of beams may vary in cost, and choosing the most cost-effective option that meets the project’s requirements can help reduce overall expenses.

Conclusion

Selecting the right type of steel beam is vital for the success of any construction project. By understanding the classifications, applications, and potential failure modes of steel beams, you can make informed decisions that enhance the safety, durability, and efficiency of your building projects.

For more detailed information on the types of steel beams and their uses, you can refer to these comprehensive guides on Types of Steel Beams and Steel Sections.

For more information or to discuss your steel beam needs, please visit our website at Lux Metal. Our team of experts is ready to assist you with all your steel fabrication requirements.