The Rise of Tech-Skilled Manufacturing

Sheet metal fabrication has come a long way from traditional methods. With the rise of CNC machines, laser cutting, 3D modeling, and other automated processes, manufacturers can now deliver more precise and intricate products than ever before. This shift towards technology-driven production ensures faster turnaround times, minimal waste, and a higher standard of quality.

At Lux Metal, we embrace this evolution. Our state-of-the-art facilities are equipped with the latest technology, including laser cutting machines, CNC machines, bending machines, and more. These tools allow us to produce custom metal solutions for a wide range of industries, tailored to meet the specific needs of our clients.

Why Tech-Skilled Partners Matter

- Precision and Accuracy: Advanced machinery allows for micron-level accuracy, ensuring that every piece of metal is cut, shaped, and finished to exact specifications. This level of precision is critical for industries where even the slightest deviation can lead to costly errors.

- Efficiency and Speed: With automation and advanced design software, tech-driven manufacturers can reduce production time without compromising quality. This means faster lead times and quicker delivery, helping businesses meet tight deadlines.

- Customization and Innovation: Modern manufacturing tools provide greater flexibility in design, allowing for highly customized solutions. Whether you need intricate patterns, unique shapes, or specialized finishes, a tech-skilled partner can bring your vision to life.

- Sustainability and Cost Savings: Technology-driven processes often result in less waste and more efficient use of materials. This not only reduces costs for the client but also minimizes environmental impact.

Key Technologies for Stainless Steel Manufacturing

The manufacturing of stainless steel, especially for customized applications, requires advanced technology to ensure durability, precision, and cost-effectiveness. Some of the latest technologies driving this sector include:

- Fiber Laser Cutting: A more energy-efficient and faster alternative to CO2 laser cutting, fiber laser technology is ideal for cutting stainless steel sheets with precision. This method delivers clean, burr-free cuts and is highly efficient for various thicknesses of stainless steel.

- CNC Punching: This technology allows for intricate perforations and designs on stainless steel with extreme accuracy. It is particularly useful for custom designs that require high repeatability and minimal human error.

- 3D Laser Welding: This advanced welding technique provides strong, precise joints with minimal heat input, making it ideal for stainless steel components. It reduces the distortion and the need for post-weld treatments, saving both time and costs.

- Automated Surface Finishing: Technologies like robotic polishing and electrochemical deburring are now widely used to give stainless steel products a high-quality, uniform finish. These techniques ensure that the surface of the stainless steel is smooth and free from imperfections.

Benefits of Partnering with a Tech-Skilled Manufacturer

The integration of advanced technology into stainless steel and sheet metal fabrication isn’t just a trend — it’s a necessity. Partnering with a tech-savvy manufacturer like Lux Metal comes with several benefits:

- Consistency Across Projects: Modern technology ensures that each product or component is created to the same high standard, regardless of the complexity of the design. This reliability builds confidence for businesses requiring uniformity in large production runs.

- Enhanced Collaboration Through Digital Design Tools: With the use of CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software, manufacturers can work closely with clients to develop precise designs. These digital tools allow for real-time modifications and ensure the design vision is accurately translated into a final product.

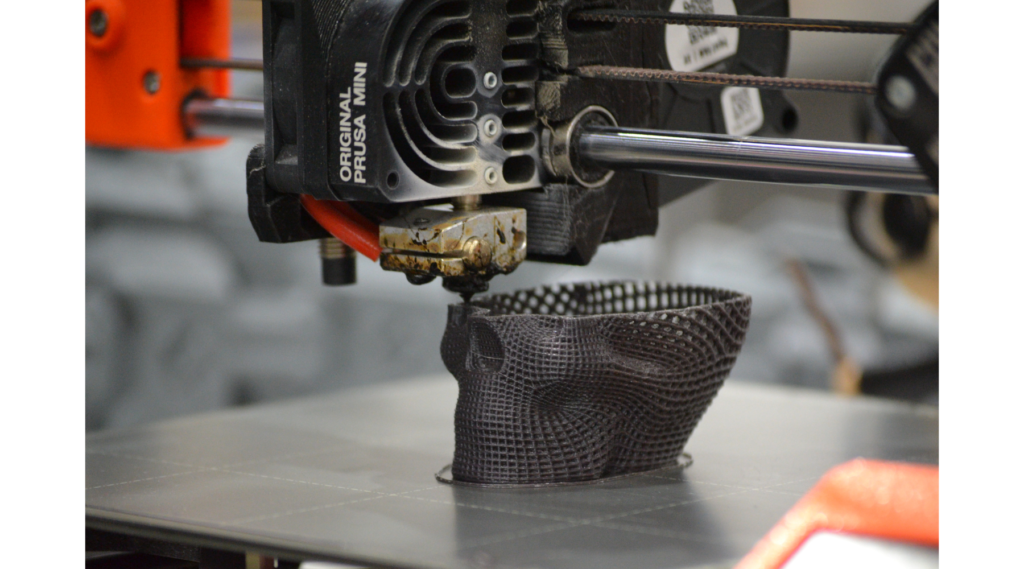

- Prototyping and Rapid Development: Technology also allows for faster prototyping and iteration. With 3D modeling and CNC machining, manufacturers can produce prototypes quickly, enabling businesses to test designs and make adjustments before committing to full-scale production. This process minimizes risk and helps ensure the final product meets all functional and aesthetic requirements.

Lux Metal’s Commitment to Innovation

At Lux Metal, we are committed to staying at the forefront of the metal fabrication industry. Our team of skilled technicians is trained to operate the latest equipment, ensuring that every project is executed with precision and care. We continually invest in new technologies to improve our capabilities, allowing us to offer our clients the best possible service.

Our range of services includes laser cutting, CNC machining, metal bending, welding, and more. We work closely with our clients to understand their specific needs and provide customized solutions that meet their requirements. With a focus on quality and innovation, Lux Metal is the trusted partner for all your sheet metal and stainless steel fabrication needs.

Conclusion

In today’s competitive market, having a sheet metal manufacturing partner who is tech-skilled is essential. Lux Metal combines cutting-edge technology with expert craftsmanship to deliver high-quality, customized metal solutions that meet the demands of modern industries. Whether you’re looking for precision, efficiency, or innovation, we have the tools and expertise to bring your project to life.

When choosing a partner for your stainless steel or sheet metal projects, it’s critical to consider their technological capabilities. The ability to leverage advanced tools and machinery can make the difference between a standard solution and a truly tailored, high-performance product.

For more information or to discuss your metal fabrication needs, visit us at Lux Metal.

Here are some suggested reference links you can consider adding to your post to provide further insights and credibility:

CNC Machining Overview

Learn about the role of CNC machines in precision manufacturing, including how they help reduce lead times, costs, and material usage in metal fabrication.

Laser Cutting Technology for Stainless Steel

Discover how laser cutting has revolutionized the fabrication of stainless steel with improvements in precision, speed, and efficiency over traditional methods.