THE BLOG

March 30, 2025

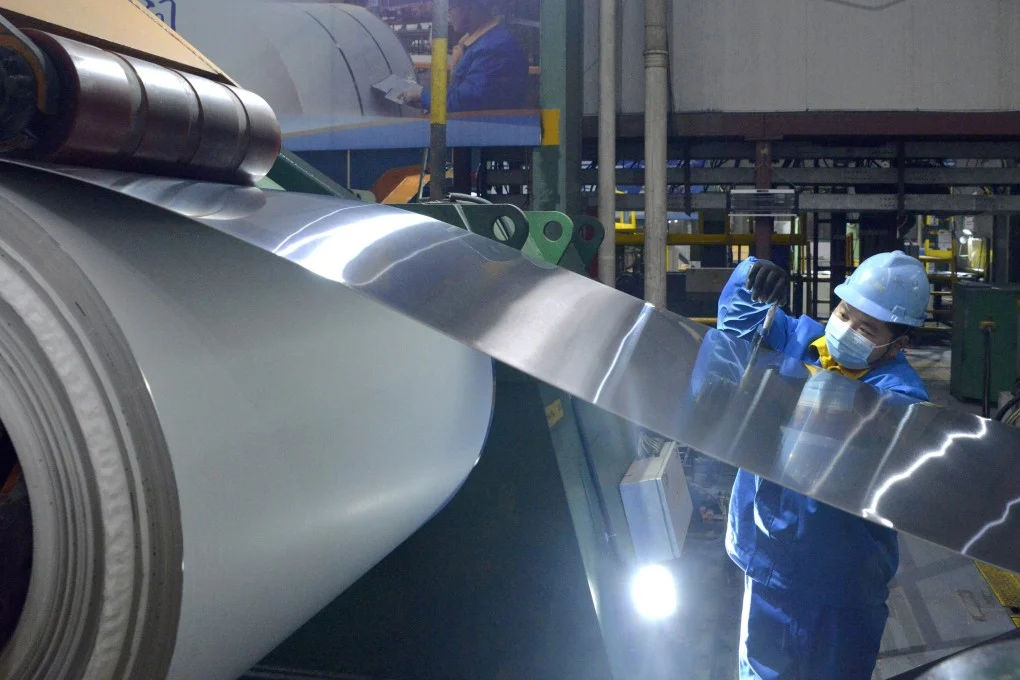

The global iron ore and steel industry saw significant shifts in 2024, with iron ore exports rising, the European Union (EU) increasing imports of direct reduced iron (DRI), and both long and flat steel product exports showing growth. These trends indicate a recovering global steel sector and highlight the evolving demand patterns and supply chain adjustments worldwide.

At LUX METAL, we specialize in high-quality stainless steel fabrication, offering customized metal solutions for various industries. Understanding global trends is crucial for businesses involved in metal manufacturing and distribution, as these changes affect raw material availability, pricing, and demand for finished steel products.

March 29, 2025

Steel is one of the most commonly used materials in construction, manufacturing, and various industrial applications. However, not all steel is created equal. Two of the most widely used types are stainless steel and mild steel—each with its own strengths, weaknesses, and ideal use cases.

Choosing the right type of steel is critical to ensuring durability, cost-effectiveness, and performance in your project. In this blog, we will compare stainless steel and mild steel in terms of composition, strength, corrosion resistance, applications, cost, and more to help you make the right decision for your specific needs.

March 27, 2025

Bangladesh is on the verge of a transformative milestone in its steel industry as Bashundhara Multi Steel Industries Ltd (BMSIL) prepares to become the country’s first-ever producer of rebar and wire rod. This development, spearheaded by the Bashundhara Group, represents a major leap forward for Bangladesh’s industrial and economic growth, reducing reliance on imports and positioning the country as a key player in the global steel market.

With an ambitious investment of Tk 150 billion (approximately $1.37 billion USD), BMSIL is set to revolutionize the local steel industry by mid-2026. This cutting-edge steel plant will not only enhance domestic steel production but also boost employment, infrastructure development, and technological advancements in Bangladesh’s manufacturing sector.

March 23, 2025

The iron ore market continues to experience a turbulent ride in 2025, with spot prices rising slightly in mid-March despite ongoing market challenges. The increase comes after months of fluctuating demand, supply chain disruptions, and economic uncertainty driven by global steel production trends and geopolitical factors.

While this slight rise offers a temporary reprieve for producers and traders, analysts predict that iron ore prices will remain under pressure throughout 2025 due to weaker demand, China’s evolving steel output strategy, and seasonal weaknesses in the market.

March 22, 2025

The United Kingdom's steel industry, a cornerstone of its manufacturing sector, is currently grappling with escalating challenges that threaten its competitiveness and sustainability. Among these challenges, soaring electricity prices and international trade tensions, particularly those arising from policies implemented by former U.S. President Donald Trump, have placed immense pressure on the industry. In response, industry leaders are advocating for government intervention to cap energy prices, aiming to level the playing field with European counterparts and safeguard the future of domestic steel production.

March 21, 2025

China has long been a dominant force in global steel production, accounting for more than half of the world’s output. The industry, however, has traditionally relied heavily on coal, making it one of the most significant contributors to carbon emissions worldwide. In a groundbreaking technological advancement, China has reportedly developed a revolutionary steel production method that is 3,600 times faster than conventional methods and does not require coal. This development marks a significant milestone in the global transition toward greener, more sustainable industrial processes.